Aircraft Docking Systems Market Outlook

The aviation maintenance industry continues to evolve alongside increasing air travel, modernization of aircraft fleets, and growing safety and efficiency demands. One critical but often overlooked component of this infrastructure is the Aircraft Docking Systems Market. A newly released study by Report reveals how the market is expanding, driven by the need for reliable and adaptable maintenance platforms that ensure smooth aircraft servicing and overhaul operations. The study explores key trends, technological innovations, growth drivers, and challenges shaping the future of the aircraft docking systems industry.

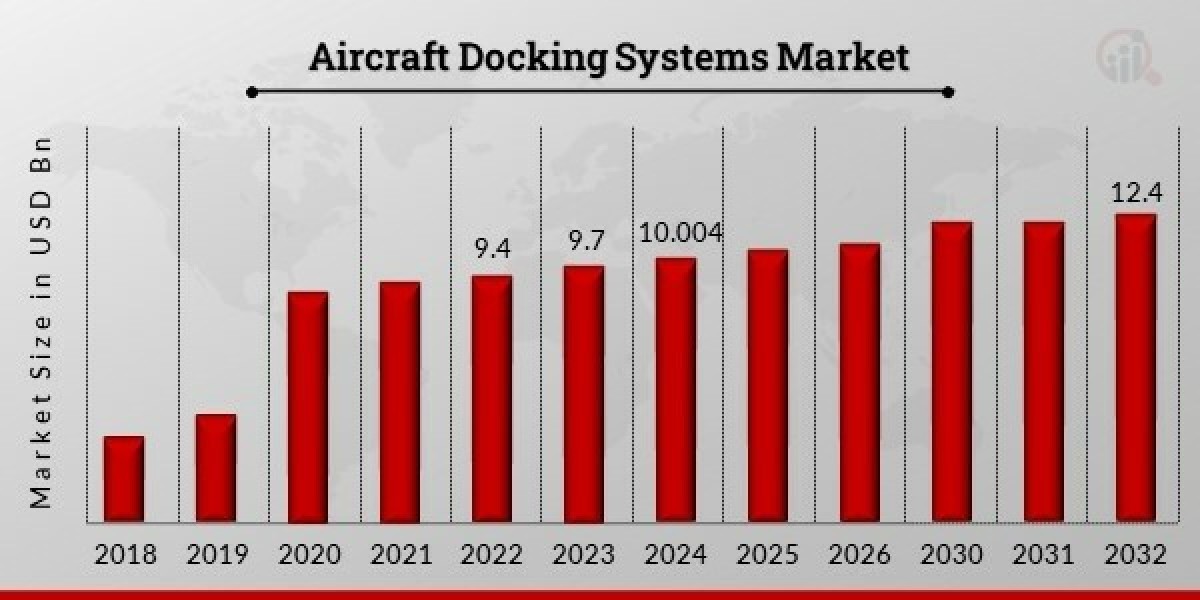

Aircraft Docking Systems Market Size was valued at USD 9.7 Billion in 2023. The Aircraft Docking Systems market industry is projected to grow from USD 10.00458 Billion in 2024 to USD 12.4 Billion by 2032, exhibiting a compound annual growth rate (CAGR) of 2.71% during the forecast period (2024 - 2032).

Rising Demand for MRO Services Fuels Market Growth

According to the report, one of the primary factors propelling the Aircraft Docking Systems Market is the increasing demand for Maintenance, Repair, and Overhaul (MRO) services. With global fleets growing and aircraft utilization rates on the rise, airlines and military operators require regular inspections and maintenance to ensure safety, compliance, and operational readiness. Docking systems provide the platforms and scaffolding necessary for technicians to access various parts of an aircraft—wings, fuselage, tail, engines—for effective servicing. As the commercial aviation industry rebounds post-pandemic, MRO demand is surging, and with it, the need for advanced docking systems.

Technological Advancements and Customization Trends

The study highlights the impact of technological innovation on the aircraft docking systems industry. Traditional steel-based structures are increasingly being replaced by modular, lightweight aluminum systems that are easier to transport, assemble, and disassemble. Many docking systems now come equipped with adjustable heights, smart sensors, integrated lighting, and safety mechanisms to prevent accidents and improve technician workflow. These features enhance productivity and enable MRO operations to be completed more quickly and with higher precision. Moreover, the rise in demand for customized docking solutions—tailored to specific aircraft models—is driving competition and innovation among manufacturers.

Growing Use of Composite Materials in Aircraft

Modern aircraft, especially new-generation commercial and military jets, often feature advanced composite materials in their design. This trend has necessitated the development of docking systems that are non-abrasive and safe for sensitive airframe surfaces. The report notes that docking system manufacturers are now producing equipment with protective padding, anti-static features, and adaptable configurations to accommodate aircraft made from carbon fiber and other high-performance materials. This shift is crucial for reducing the risk of damage during maintenance and ensuring long-term operational reliability.

Get a Quote - Request a price quote for the report or specific research services.

Integration with Smart Hangar Infrastructure

Another significant market trend, as outlined in the study, is the integration of aircraft docking systems with digital and smart hangar technologies. As MRO facilities move toward automation and data-driven maintenance practices, docking systems are evolving to become part of the connected ecosystem. Features such as RFID tracking for component use, digital monitoring of dock usage, and automated movement systems are being tested and implemented in modern hangars. This not only streamlines operations but also enhances inventory management, safety compliance, and overall workflow efficiency.

Defense and Military Sector Driving Specialized Demand

While commercial aviation dominates the aircraft docking systems market, the defense and military sector is playing an increasingly important role. Military aircraft, including cargo planes, fighters, and helicopters, require specialized docking systems for periodic and mission-specific maintenance. The study notes that governments across the globe are investing in expanding and upgrading military MRO facilities, which includes the procurement of versatile and heavy-duty docking platforms. These systems must meet unique operational requirements, including rapid deployment, transportability to remote locations, and compatibility with a wide range of aircraft types.

Regional Growth and Emerging Markets

Geographically, North America and Europe lead the market due to the presence of major aircraft manufacturers, well-developed MRO networks, and strong defense aviation infrastructure. However, the report emphasizes that the Asia-Pacific region is the fastest-growing market for aircraft docking systems. Rapid growth in commercial aviation in countries like China, India, and Southeast Asia, coupled with increasing investments in regional MRO hubs, is generating strong demand. Governments in these regions are promoting indigenous aviation manufacturing and maintenance capabilities, creating new opportunities for docking system suppliers.

Challenges: High Initial Investment and Customization Costs

Despite positive growth prospects, the Aircraft Docking Systems Market faces several challenges. The report identifies high capital investment as a major barrier, especially for small MRO operators and regional airports. Custom-built docking systems designed for specific aircraft types can be expensive, and their assembly requires time, specialized labor, and logistics support. Additionally, ensuring global safety compliance and regulatory approvals adds to the cost and complexity of product deployment. Market players must find ways to offer more cost-effective, modular, and scalable solutions to broaden their reach and appeal.

Opportunities in Sustainable and Eco-Friendly Designs

As environmental sustainability becomes a core focus in aviation, there is an emerging opportunity in the development of eco-friendly docking systems. Manufacturers are exploring recyclable materials, energy-efficient components (like solar-powered lighting), and low-carbon production methods to align with green aviation goals. The report suggests that companies investing in sustainable designs and low-emission manufacturing processes will have a competitive edge in the coming years.

About US

Market Research Future (MRFR) is a global market research company that takes pride in its services, offering a complete and accurate analysis with regard to diverse markets and consumers worldwide. Market Research Future has the distinguished objective of providing the optimal quality research and granular research to clients. Our market research studies by products, services, technologies, applications, end users, and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help answer your most important questions.

Contact US

Market Research Future (part of Wantstats Research and Media Private Limited),

99 Hudson Street,5Th Floor New York 10013, United States of America

Sales: +1 628 258 0071 (US) +44 2035 002 764 (UK)

Email: Sales@marketresearchfuture.com

Website: www.marketresearchfuture.com