Market Overview:

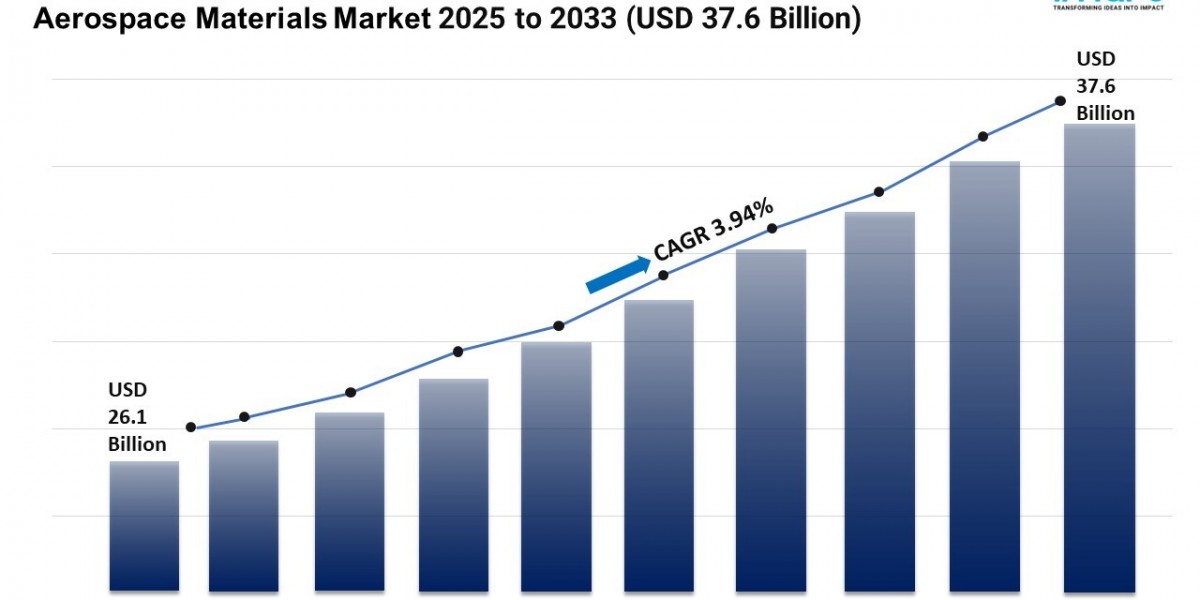

The Aerospace Materials Market is experiencing steady expansion, driven by Rising Demand for Fuel Efficiency and Sustainability, Increasing Investment in Research and Development (R&D), and Growing Air Cargo and Logistics Requirements. According to IMARC Group's latest research publication, "Aerospace Materials Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", The global aerospace materials market size reached USD 26.1 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 37.6 Billion by 2033, exhibiting a growth rate (CAGR) of 3.94% during 2025-2033

This detailed analysis primarily encompasses industry size, business trends, market share, key growth factors, and regional forecasts. The report offers a comprehensive overview and integrates research findings, market assessments, and data from different sources. It also includes pivotal market dynamics like drivers and challenges, while also highlighting growth opportunities, financial insights, technological improvements, emerging trends, and innovations. Besides this, the report provides regional market evaluation, along with a competitive landscape analysis.

Download a sample PDF of this report: https://www.imarcgroup.com/aerospace-materials-market/requestsample

Our Report Includes:

- Market Dynamics

- Market Trends and Outlook

- Competitive Analysis

- Industry Segmentation

- Strategic Recommendations

Key Trends in the Aerospace Materials Market:

- Rising Demand for Fuel Efficiency and Sustainability

The aerospace materials sector is progressively influenced by the rising worldwide focus on fuel efficiency and ecological sustainability. With increasing regulatory pressures and client demands for lower emissions, better energy efficiency, and minimized environmental effects, material innovation is essential in the aerospace industry. To achieve these goals, manufacturers are focusing on the creation and implementation of innovative, lightweight materials that significantly decrease fuel usage while maintaining the strength, durability, and safety of aircraft. Furthermore, there is a higher emphasis on utilizing sustainable materials, such as recyclable composites and environment-friendly manufacturing techniques that reduce waste production. This change corresponds with the larger dedication of the industry to environmental responsibility and tackles sustainability issues. Additionally, the upcoming generation of aircraft design incorporates these sustainability principles, creating a substantial need for novel materials that enhance both performance and ecological objectives.

- Increasing Investment in Research and Development (R&D)

There is rise in the investments in research operations, with governments, private companies, and universities dedicating considerable resources to developing new materials that cater to the changing requirements of aerospace uses. This encompasses studies aimed at enhancing mechanical strength, thermal stability, and minimizing material weight, all of which are vital for achieving the demanding performance requirements of contemporary aircraft and space exploration technologies. Joint efforts, like the 2024 establishment of Alfred University's Space Materials Institute, illustrate the increasing importance of academia in progressing aerospace materials science. Collaborating with NASA, the US Army, and industry partners, the institute engaged in advanced projects like lunar regolith simulants and ultra-high temperature ceramics. This initiative enhanced hands-on student learning and supported innovation in aerospace materials. Such efforts expedite material innovations, guaranteeing the aerospace industry stays at the leading edge of technological progress and upholds its ability to achieve global efficiency and sustainability objectives.

- Growing Air Cargo and Logistics Requirements

The aerospace materials industry is witnessing growth, driven by the swift development of international air cargo and logistics activities. As the worldwide e-commerce market reached USD 26.8 Trillion in 2024, as per the IMARC Group, the need for freighter planes and cargo modifications is increasing significantly. This growing scale of air cargo activities, driven by expanding e-commerce and global trade, guarantees ongoing demand for these resources in both the production of new aircraft and upgrades to current fleets. This is leading to the development of materials that provide lightweight design and improved durability to optimize payload efficiency while reducing operational expenses. Specialized materials are necessary for structural reinforcements, floor panels, and cargo handling systems to ensure they endure heavy use without sacrificing safety. These advancements further underscore the essential function of aerospace materials in facilitating international trade, enhancing logistics operations, and increasing the aviation sector's impact on global supply chains.

Growth Factors in the Aerospace Materials Market Industry:

- Rising Passenger Traffic and Tourism Growth

The increase in global passenger traffic, which is supported by the resurgence of tourism, is propelling the market growth. According to the latest World Tourism Barometer by UN Tourism, approximately 790 million tourists traveled internationally in the first seven months of 2024, significantly boosting the demand for air travel. As airlines expand their fleets and upgrade existing aircraft to meet this growing demand, there is a rise in the need for materials that improve performance, reliability, and fuel efficiency. Additionally, heightened passenger expectations for comfort, safety, and modernized cabin features are catalyzing the demand for advanced interior materials, such as lightweight composites and durable finishes. The robust tourism sector directly translates into sustained demand for high-performance aerospace materials, ensuring continued growth in the industry and contributing to the broader aerospace sector's capacity to meet the evolving needs of global air travel.

- Infrastructure Development in Aviation Hubs

Global investments in aviation infrastructure are driving the demand for aerospace materials. As nations continue to expand and modernize airports, maintenance centers, and manufacturing hubs, there is an increase in the need for high-quality, locally produced materials. These investments are critical in establishing regional supply chains and production bases that ensure consistent access to aerospace-grade materials, reducing reliance on imports and minimizing lead times. For example, in 2025, Adani Airports Holdings Ltd raised $1 billion for the modernization and capacity expansion of Mumbai International Airport, marking India's first investment-grade private bond in airport infrastructure. This funding will support sustainability efforts and a net-zero emissions target by 2029. Such large-scale infrastructure projects often foster partnerships between governments and industry leaders, promoting the growth of domestic material manufacturing. These developments reinforce the steady demand for aerospace materials, positioning them as a cornerstone of both civil and defense aviation projects, ensuring continued market growth and innovation.

- Increased Focus on Lifecycle Cost Reduction

The strategic focus on reducing the overall lifecycle costs of aircraft, which remains a decisive factor in procurement and operational planning, is contributing to the market growth. Airlines, defense organizations, and space agencies are increasingly prioritizing materials that demonstrate extended durability, lower maintenance demands, and superior performance under demanding operating conditions. Such materials not only minimize downtime and maintenance expenses but also contribute to enhanced fuel efficiency and reliability, ultimately lowering long-term operating costs. Manufacturers and operators are aligning investments toward solutions that resist wear, withstand extreme environments, and ensure consistent performance across the entire service life of aircraft. This emphasis on lifecycle value extends beyond initial acquisition, influencing design innovations, supplier partnerships, and maintenance strategies. By concentrating on cost-effectiveness without compromising safety or efficiency, the industry ensures steady demand for advanced materials.

Leading Companies Operating in the Global Aerospace Materials Market Industry:

- Arconic Corporation

- Arkema S.A.

- ATI Corporate

- BASF Corporation

- Constellium N.V

- Huntsman International LLC

- Kaiser Aluminum

- Materion Corporation

- Mitsubishi Chemical Group

- Novelis

- Park Aerospace Corp.

- Röchling Industrial

- SGL Carbon

Aerospace Materials Market Report Segmentation:

Breakup by Type:

- Aluminium Alloys

- Titanium Alloys

- Super Alloys

- Steel Alloys

- Composite Materials

Aluminium Alloys exhibited a clear dominance in the market due to their lightweight and high strength-to-weight ratio, which aids in increasing fuel efficiency, reducing operating costs, and improving the overall performance of aircraft.

Breakup by Aircraft Type:

- Commercial Aircraft

- Business and General Aviation

- Helicopters

Commercial Aircraft exhibited a clear dominance in the market owing to the rapid expansion of the commercial aircraft business.

Breakup by Application:

- Interior

- Passenger Seating

- Galley

- Interior Panels

- Others

- Exterior

- Propulsion Systems

- Air Frame

- Tail and Fin

- Windows and Windshields

Exterior exhibited a clear dominance in the market due to the widespread product utilization in the fuselage, wings, windows, propulsion systems, and empennage.

Breakup by Region:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

North America dominated the global market owing to the presence of a well-established aerospace industry comprising major aircraft manufacturers and suppliers.

Note: If you require specific details, data, or insights that are not currently included in the scope of this report, we are happy to accommodate your request. As part of our customization service, we will gather and provide the additional information you need, tailored to your specific requirements. Please let us know your exact needs, and we will ensure the report is updated accordingly to meet your expectations.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States:+1-201-971-6302