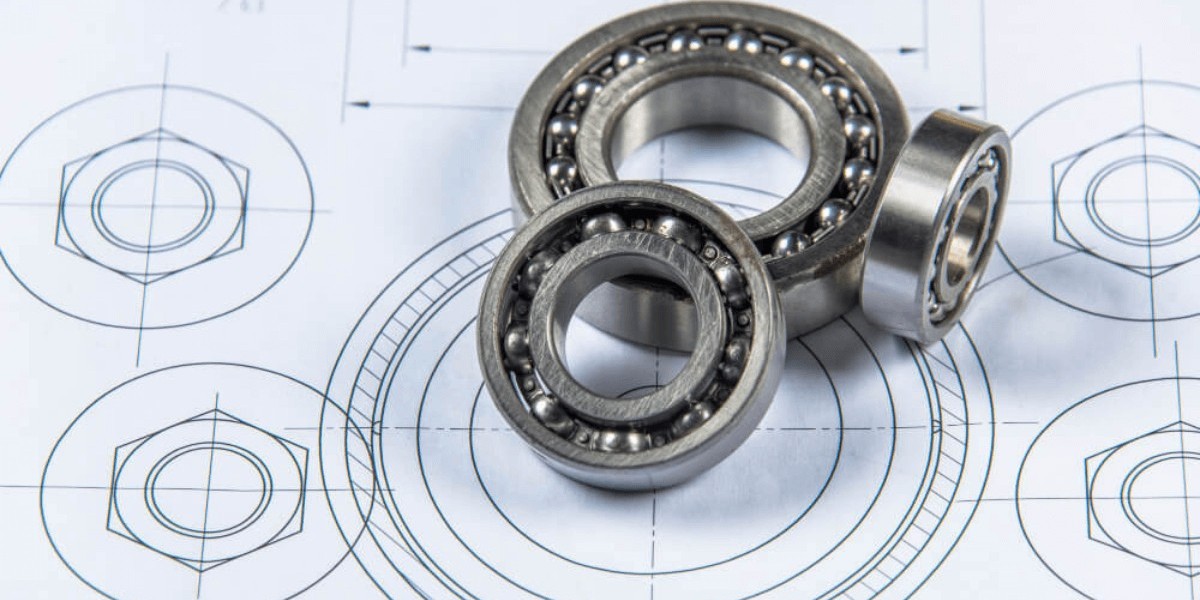

Mechanical breakdowns often start small, but a failing bearing can quickly escalate into a costly shutdown. Excessive noise, vibration, or overheating are not just minor inconveniences, they are warning signs that your equipment is under serious stress. Many operators overlook bearing quality until production stops and repair costs begin to climb.

Choosing a dependable bearing such as vkjp84887 plays a critical role in preventing these avoidable failures.

How Bearing Failure Impacts Performance and Safety

Bearings are responsible for supporting loads while enabling smooth rotational motion. When a bearing wears out or fails prematurely, friction increases and alignment suffers. This added strain affects shafts, housings, and connected components, often leading to secondary damage.

Using a precision-engineered solution like vkjp84887 helps maintain proper motion control and reduces the likelihood of unexpected equipment failure.

Why VKJP84887 Is Built for Demanding Conditions

VKJP84887 is designed to perform reliably under continuous load and repetitive motion. Its construction allows for balanced load distribution and stable rotation, which are essential in both industrial and mechanical applications.

Key advantages include:

Smooth and consistent rotation

Reduced friction and heat buildup

Improved resistance to wear

Reliable performance under sustained operation

These features help extend bearing life and reduce the frequency of maintenance interventions.

Problems Caused by Inferior or Worn Bearings

Low-quality or damaged bearings often create problems that worsen over time. Increased vibration can loosen fasteners, damage seals, and reduce overall machine accuracy. In many cases, what starts as a bearing issue ends with major component replacement.

By selecting vkjp84887, operators can significantly lower the risk of recurring breakdowns and protect surrounding mechanical parts from premature wear.

Improving Energy Efficiency Through the Right Bearing Choice

Bearings directly affect how efficiently a machine operates. Excessive friction forces motors to work harder, increasing energy consumption and operating costs. A high-quality roller ball bearing minimizes resistance, allowing smoother motion with less power loss.

Installing vkjp84887 helps improve system efficiency while maintaining consistent speed and load handling.

Applications Where Bearing Reliability Is Critical

Reliable bearings are essential in systems that operate continuously or under variable loads. These include industrial machinery, automotive components, mechanical assemblies, and manufacturing equipment where downtime is not an option.

In such environments, consistent bearing performance ensures operational stability and reduces the risk of unplanned stoppages.

Warning Signs That Indicate Immediate Replacement

Delaying bearing replacement often leads to higher repair costs. Common signs that should never be ignored include:

Grinding, humming, or knocking noises

Excessive vibration during operation

Increased operating temperature

Irregular or unstable rotation

Replacing a failing bearing early helps prevent damage to more expensive components.

Long-Term Benefits of Choosing VKJP84887

Investing in a reliable bearing offers long-term advantages beyond immediate performance. Reduced maintenance, extended equipment life, and improved operational reliability all contribute to lower total ownership costs.

Quality bearings also support smoother workflows, fewer interruptions, and better overall productivity.

Final Thoughts

A single bearing failure can disrupt operations and strain budgets, but the right component choice makes a measurable difference. VKJP84887 provides durability, stability, and consistent performance for demanding mechanical applications. Proactive bearing selection and timely replacement protect your equipment, reduce downtime, and ensure dependable operation over the long term.