In modern industrial laser applications, the laser galvo scanner plays a critical role in achieving high-speed and high-precision laser processing. By using fast-responding galvanometer motors and precise optical control, a galvo laser system can accurately direct the laser beam to any position within the working field, making it ideal for marking, engraving, welding, and surface treatment.

2D Galvo Scanner for Planar Laser Processing

A 2D galvo scanner is the most commonly used solution in laser marking and engraving systems. It controls the laser beam along the X and Y axes, enabling fast and accurate planar scanning. With a well-optimized galvo laser setup, a 2D galvo scanner can deliver excellent performance in applications such as metal marking, plastic engraving, PCB processing, and barcode or logo marking.

Thanks to its compact structure and stable control, the 2D galvo scanner is widely integrated into fiber, CO₂, and UV laser systems, offering a reliable balance between speed, accuracy, and cost.

3D Galvo Scanner for Advanced Depth and Surface Control

For applications that require depth control or processing on curved and uneven surfaces, a 3D galvo scanner provides a more advanced solution. Unlike traditional 2D systems, a 3D galvo scanner adds dynamic Z-axis focusing, allowing the galvo laser to maintain a consistent focal point across different heights.

This capability makes 3D galvo scanners ideal for deep engraving, 3D marking, mold texturing, and high-end industrial laser processing. When combined with advanced laser control software, a 3D galvo scanner significantly improves processing quality and flexibility.

Galvo Laser Systems in Industrial Applications

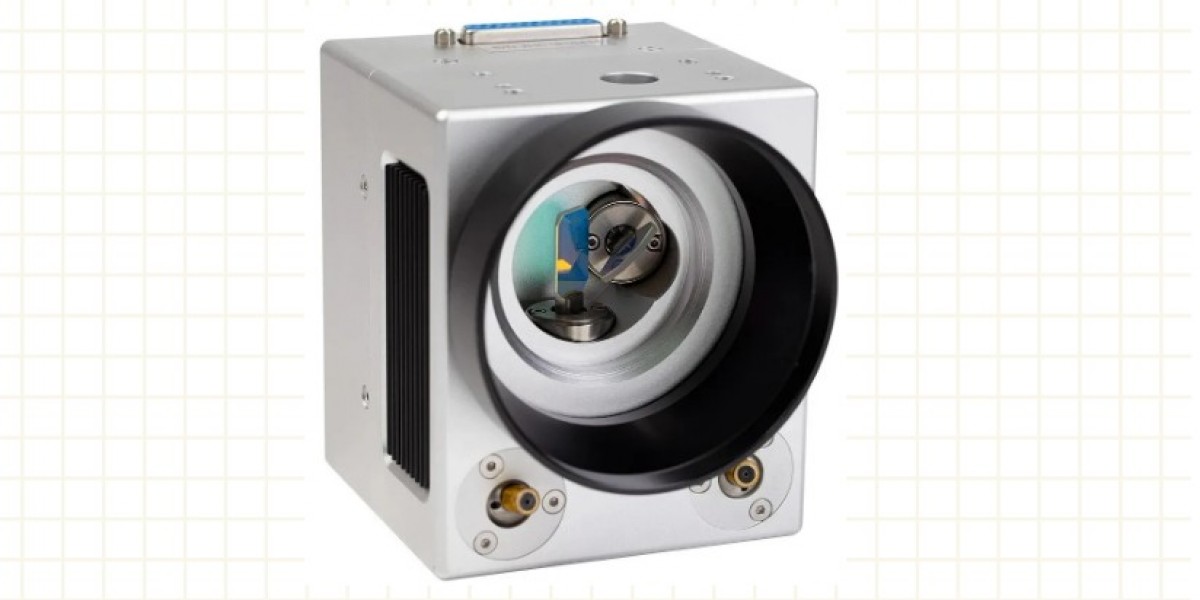

A complete galvo laser system typically consists of a laser source, laser galvo scanner, control electronics, and dedicated laser software. The synergy between these components determines the overall system performance. High-quality laser galvo scanners ensure fast response times, minimal drift, and long-term stability, which are essential for continuous industrial operation.

Industries such as automotive, electronics, medical devices, and precision manufacturing rely heavily on galvo laser systems to achieve consistent results and high production efficiency.

Choosing the Right Laser Galvo Scanner

Selecting the right laser galvo scanner depends on several factors, including scanning speed, positioning accuracy, aperture size, and application requirements. While a 2D galvo scanner is sufficient for most flat-surface tasks, a 3D galvo scanner offers greater versatility for complex and high-value laser applications.

As galvo laser technology continues to evolve, advanced scanners and intelligent control systems are helping manufacturers push the limits of laser precision and productivity.