Modern industries demand accuracy, speed, and flexibility like never before. From industrial machinery to architectural structures, manufacturers depend on state-of-the-art processes to produce components that strictly comply with quality and performance standards. Among these processes come fabrication and laser cutting, which are the epitome of technologies that ensure efficiency and innovation across a wide array of sectors.

With a combination of precision engineering and high-level automation, such techniques allow manufacturers to create very complicated parts with great accuracy. In cases where companies have Customized Manufacturing Services to support them, it enables these businesses to provide solutions that cater to particular project needs for consistent quality, less waste, and quicker turnaround times.

Understanding Fabrication and Laser Cutting

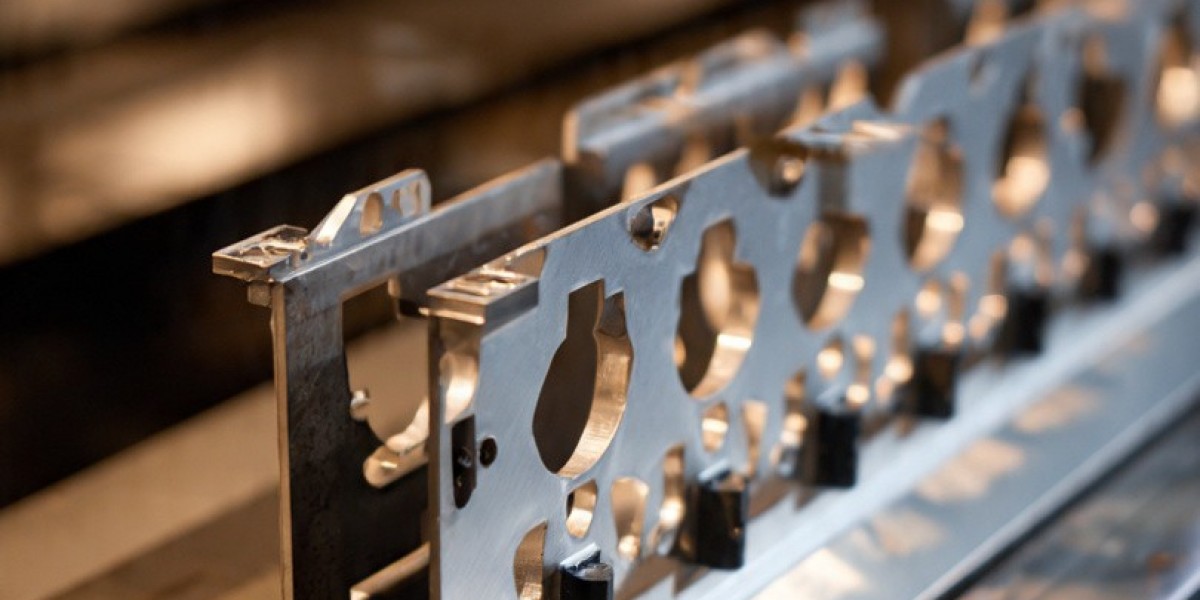

Fabrication:It involves working with materials like steel, aluminum, and stainless steel to create an object. The process involves cutting, bending, welding, and assembling. Laser Cutting:Improve the manufacturing process with laser cutting that uses high-powered laser beams to make precise cuts.

Together, fabrication and laser cutting bring manufacturers:

Higher dimensional accuracies

Well-defined, clean edges

Very little material wastage

Shorter production cycles

All these factors make the process perfect for mass production as well as customized tasks.

Important Benefits of Fabrication & Laser Cutting

Precision and Accuracy Precision and accuracy

The technology has the ability to provide highly precise tolerances, guaranteeing that all the parts meet the required specifications. This is particularly important in industries that require precise measurements to perform their operations.

Design Flexibility

Even intricate geometries, designs, and cutouts can be realized with this manufacturing process without affecting the structure’s stability and integrity.

Efficiency And Cost Control

Automation minimizes human labor, increases production speed, and decreases errors. With time, it results in decreased operating costs.

Reliable Quality

Repeatable processes enable similar quality to be produced in each batch, and this becomes an important factor in the context of large-scale projects such as mass manufacturing

Together with the use of Customized Manufacturing Services, the benefits will be strengthened for businesses to adapt to changing requirements in projects.

Industries and Uses

Both Industrial Fabrication & Cutting are widely exercised because of their versatility and dependability.

Industrial Manufacturing

Precision-cut components are employed in machines, manufacturing equipment, and assembled structures.

Oil & Gas

Custom-made components provide support for pipelines, process equipment, and protective enclosures that are able to operate effectively in severe environments.

Construction and Infrastructure

Laser-cut steel and fabricated parts are needed in the construction of the frame and supports and in architectural components.

Automotive and Transportation

Precision components enhance performance, safety, and durability in vehicles and transportation networks.

Through Customized Manufacturing Services, all industries get to benefit from the solutions that are tailored specifically for them.

Material that Can Be Sourced from the Nature

The choice of suitable material plays a pivotal role in performance and durability.

Materials that are commonly employed are:

Mild Steel For Structural Strength

Aluminum for Lightweight Applications

Special alloys designed to operate in high temperature or high-stress applications

Modern Industrial Fabrication & Cutting methods can process such materials with precision and speed, without affecting the properties in the process.

The Function of Customization in Contemporary Manufacturing

Sometimes, standard components cannot fulfill the requirements of unique operations. Custom manufacturing helps to produce parts that fit perfectly according to business specifications.

Benefits of Custom Manufacturing

Better component compatibility

Lower demand for modulation changeover

Improved performance and durability

Integration with Other Systems

Learned: This module

With Customized Manufacturing Services, manufacturers can create tailored solutions that help optimize operational efficiency over the long run.

Quality Control and Compliance Standards

Quality assurance is an essential element in the Industrial Fabrication & Cutting procedure as well. High technology inspection equipment and rigorous quality inspections guarantee that all components comply with industrial standards.

Key quality measures are:

Dimensional inspection

Material Verification

Surface finish evaluation

Adherence to ISO standards & industry norms

Such methods provide reliability, safety, and consistency for all the manufactured components.

How Advanced Technology Improves Fabrication Efficiency

Technology has greatly enhanced the manufacturing process.

Integrating CNC

Computer-controlled systems offer high-accuracy and repeatability, increasing production speeds.

Automation and Robotics

Automated handling minimizes human error and maximizes workplace safety.

Digital Design Integration

CAD and CAM systems guarantee smooth translation from design to production.

These technologies, if supported by the services of Specialized Manufacturing Services, enable the manufacturer to provide precision-driven results with shorter lead times.

Conclusion

In today’s competitive industrial era, accuracy and flexibility are key to success. Fabrication and laser cutting are the tools that would allow the manufacturer to create high-quality parts successfully and efficiently. Fabrication and laser cutting are associated with innovation, minimizing waste, and improving the performance of the final product in the market.

When paired with Customized Manufacturing Services, a company has the ability to handle the specific requirements of their operation with the ability to provide quality and consistency. It is more than just an investment in manufacturing tools when acquiring advanced fabrication technology.

FAQs

1. What is fabrication and laser cutting used for?

It is used to create precise metal and material components for industrial, commercial, and infrastructure applications.

2. How does laser cutting improve accuracy?

Laser cutting uses focused beams to produce clean, precise cuts with minimal distortion.

3. Can fabrication processes be customized?

Yes, Specialized Manufacturing Services allow parts to be designed and produced according to specific project requirements.

4. Which materials are best for laser cutting?

Steel, stainless steel, aluminum, and specialized alloys are commonly used due to their compatibility with laser technology.

5. How does quality control impact manufacturing outcomes?

Strict quality control ensures consistency, safety, and compliance with industry standards, reducing failures and rework.