Introduction

The In-Circuit Test Market is a vital segment of the electronics testing and quality assurance industry, supporting the reliable production of printed circuit boards and electronic assemblies. In-circuit testing is a method used to verify the electrical performance of individual components mounted on a PCB by probing specific test points on the board. This testing approach checks parameters such as resistance, capacitance, voltage, current, shorts, opens, and component orientation, ensuring that each component functions correctly and is properly placed. In-circuit testing is widely used in industries including consumer electronics, automotive electronics, industrial automation, telecommunications, medical devices, aerospace, and defense. As electronic products become more complex and reliability requirements increase, in-circuit testing remains a fundamental process for detecting manufacturing defects early, reducing rework costs, and ensuring consistent product quality.

Market Drivers

One of the primary drivers of the In-Circuit Test Market is the rapid growth of electronics manufacturing across multiple industries. Rising demand for consumer electronics, electric vehicles, industrial automation equipment, and connected devices is increasing PCB production volumes, directly driving the need for efficient testing solutions. Another key driver is the growing complexity of electronic assemblies, which include densely populated boards, multi-layer designs, and fine-pitch components. In-circuit testing provides precise fault isolation at the component level, making it highly valuable in identifying defects that may not be easily detected through functional testing alone. Increasing emphasis on product reliability and safety, particularly in automotive, medical, and aerospace applications, is also boosting adoption. Additionally, manufacturers are under pressure to reduce production defects, warranty costs, and recalls, making in-circuit testing an essential quality control tool. Automation in electronics manufacturing further supports market growth, as in-circuit testers integrate seamlessly into automated production lines.

Market Challenges

Despite its importance, the In-Circuit Test Market faces several challenges. High initial investment cost for in-circuit test systems, fixtures, and software can be a barrier for small and medium-sized manufacturers. Custom test fixtures must be designed for each PCB layout, increasing setup time and cost, especially for high-mix, low-volume production environments. Miniaturization of electronic components and increasing use of surface-mount technology reduce available test points, making probing more difficult. Design-for-test considerations must be incorporated early in the PCB design process, which requires close collaboration between design and manufacturing teams. Additionally, in-circuit testing alone cannot fully validate functional performance of complex systems, necessitating complementary testing methods. Skilled personnel are required to develop test programs, interpret results, and maintain equipment, adding to operational complexity.

Market Opportunities

The market offers strong opportunities driven by technological advancement and evolving manufacturing needs. Development of advanced probing technologies, such as boundary scan integration and flying probe in-circuit testers, is addressing challenges related to dense and miniaturized PCB designs. Growth of automotive electronics, particularly in electric vehicles and advanced driver assistance systems, is creating sustained demand for high-reliability testing solutions. Emerging markets with expanding electronics manufacturing capacity present significant growth potential. Integration of in-circuit testing with data analytics and manufacturing execution systems enables real-time quality monitoring, yield improvement, and predictive defect analysis. Increasing adoption of Industry 4.0 and smart factory concepts is also creating opportunities for connected and automated test systems. Additionally, demand for testing services from contract manufacturers and electronics manufacturing service providers is expanding, further supporting market growth.

Regional Insights

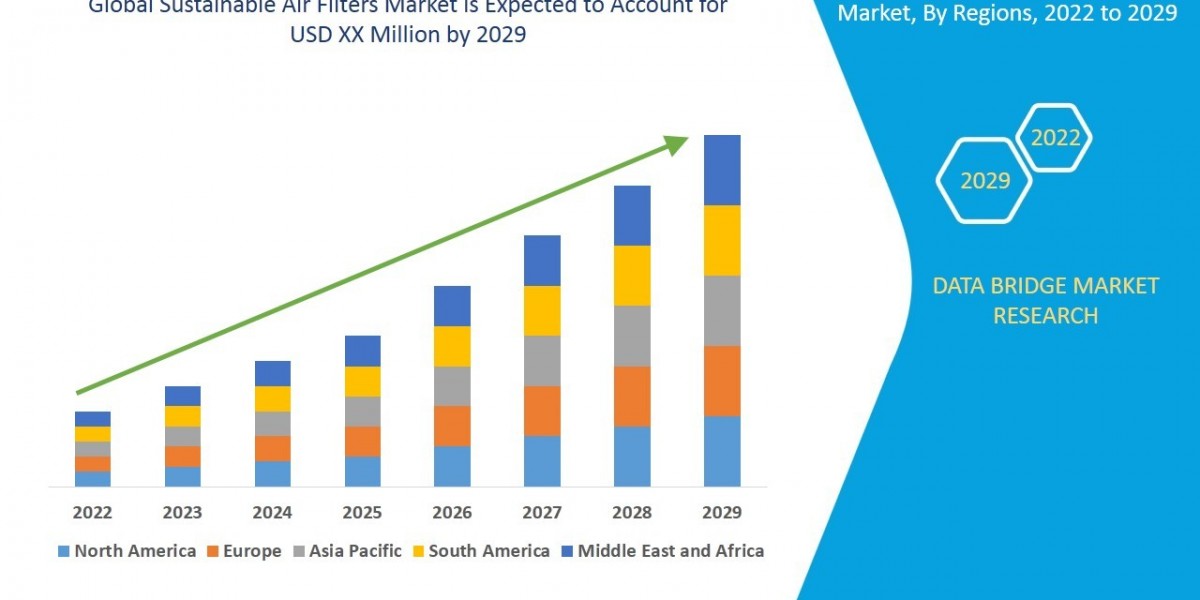

Asia-Pacific holds a dominant share of the In-Circuit Test Market due to its large electronics manufacturing base and presence of major contract manufacturers. Countries in this region produce high volumes of consumer electronics, automotive electronics, and industrial components, driving strong demand for PCB testing solutions. North America represents a mature market supported by high-reliability applications in aerospace, defense, medical devices, and advanced automotive systems. Europe also plays an important role, driven by strong automotive and industrial automation sectors and strict quality standards. Emerging markets in Latin America, the Middle East, and Africa are gradually increasing adoption as electronics manufacturing expands and quality requirements rise. Regional growth is closely linked to investment in electronics production capacity and technological sophistication.

Future Outlook

The future outlook for the In-Circuit Test Market is positive as electronics continue to penetrate every aspect of modern life. Technological innovation will focus on improving test coverage, reducing fixture dependency, and enhancing compatibility with highly integrated and miniaturized designs. Hybrid testing approaches that combine in-circuit testing with functional and boundary scan methods are expected to gain traction. Automation, artificial intelligence, and data-driven quality management will further enhance the value of in-circuit testing by enabling faster fault diagnosis and continuous process improvement. As manufacturers strive for zero-defect production and higher yields, in-circuit testing will remain a critical component of comprehensive electronics test strategies.

Conclusion

The In-Circuit Test Market plays an essential role in ensuring quality, reliability, and performance of electronic assemblies across industries. Driven by growth in electronics manufacturing, increasing product complexity, and rising quality expectations, the market continues to expand globally. Although challenges related to cost, fixture design, and miniaturization persist, technological advancements and smart manufacturing practices are addressing these issues. With electronics becoming more integral to automotive, industrial, and consumer applications, in-circuit testing is set to remain a cornerstone of modern electronics production and quality assurance.