Electric motors and transformers operate under continuous electrical and thermal stress, making insulation materials a critical factor in long-term performance and safety. Manufacturers must balance insulation reliability with cost efficiency, especially in large-scale production. 3240 epoxy laminates have become a widely used insulation solution for motors and transformers due to their practical performance and economical advantages.

3240 epoxy laminate is a glass-fiber-reinforced epoxy resin material that offers stable electrical insulation and sufficient mechanical strength for many industrial applications. Its balanced properties make it suitable for use in both low- and medium-voltage electrical equipment.

Insulation Requirements in Motors and Transformers

Motors and transformers require insulation materials that can reliably isolate conductive components while maintaining structural integrity during operation. Common insulation challenges include continuous voltage stress, heat generation, mechanical vibration, and long service life expectations.

Insulation components such as support plates, slot wedges, phase separators, and structural barriers must maintain consistent electrical properties and resist deformation over time. Failure in any of these areas can result in reduced efficiency, increased maintenance, or premature equipment failure.

Electrical and Thermal Performance of 3240 Epoxy Laminates

3240 epoxy laminates offer excellent dielectric strength, providing effective electrical insulation under continuous operating conditions. The epoxy resin system provides reliable insulation performance, reducing the risk of electrical breakdown and leakage currents.

In terms of thermal performance, 3240 materials can withstand the typical operating temperatures found in motors and transformers. Their thermal stability helps maintain dimensional integrity, preventing warping or cracking caused by heat exposure during long-term operation.

Mechanical Strength and Structural Support

In addition to insulation performance, 3240 epoxy laminates offer sufficient mechanical strength for use as structural insulation components. The fiberglass reinforcement provides rigidity and load-bearing capability, allowing the material to support internal components and withstand mechanical vibration.

This combination of electrical insulation and mechanical strength makes 3240 epoxy laminates suitable for applications where insulation components also serve a structural function.

Cost Efficiency and Manufacturing Advantages

One of the key reasons manufacturers choose 3240 epoxy laminates is their cost-effectiveness. Compared to higher-grade epoxy glass laminates, 3240 provides reliable performance at a more economical material cost, making it suitable for volume production.

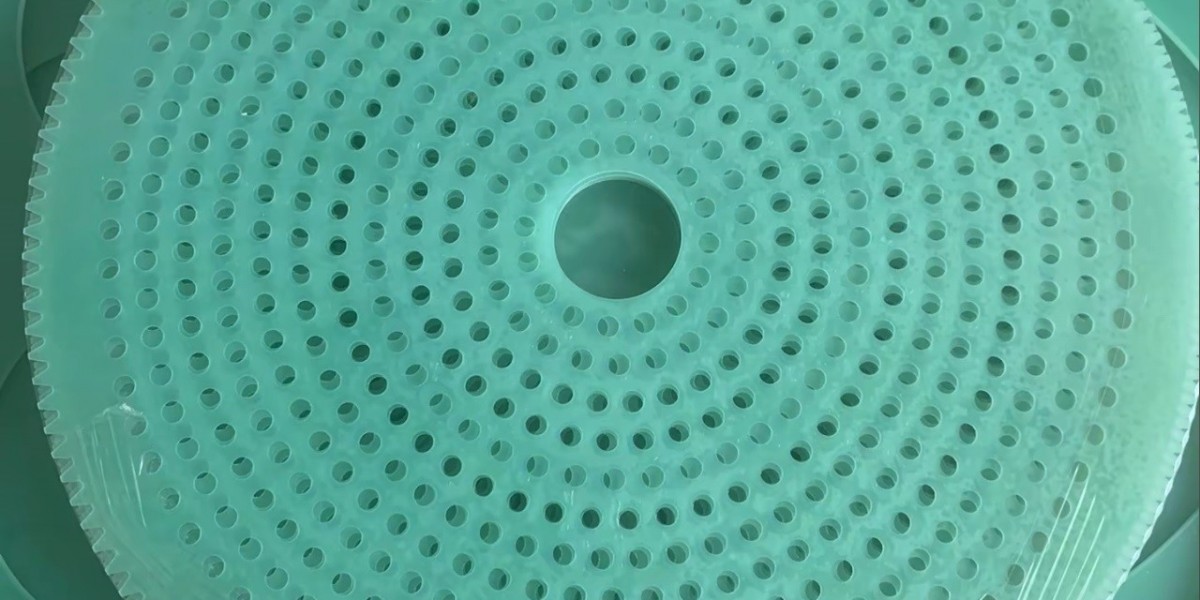

3240 epoxy laminates are also easy to machine using CNC processes. Custom parts can be produced efficiently with consistent quality, helping reduce production time and overall manufacturing costs.

Typical Applications in Motors and Transformers

Common applications of 3240 epoxy laminates include:

Motor insulation plates and support components

Transformer insulation barriers and structural parts

Slot wedges and spacers

Electrical insulation panels within housings

These components play a critical role in ensuring stable electrical performance and mechanical reliability.

Conclusion

3240 epoxy laminates offer a practical and cost-effective insulation solution for motors and transformers. With balanced electrical insulation, thermal stability, mechanical strength, and good machinability, they meet the essential requirements of many industrial electrical applications.

For manufacturers seeking dependable insulation materials that help control costs without sacrificing performance, 3240 epoxy laminates remain a proven and widely adopted choice.