Steel continues to be the backbone of modern infrastructure, automotive, and manufacturing industries, and ferro-manganese plays a pivotal role in enhancing its properties. By acting as a deoxidizing agent and improving hardness and strength, ferro-manganese ensures the production of durable, high-quality steel suitable for a variety of industrial applications. The consistent demand for ferro-manganese reflects the ongoing growth of the global steel and construction sectors.

The Ferro-Manganese Market is expanding due to increased infrastructure development, industrialization, and rising demand for steel in emerging economies. Automotive manufacturing, machinery production, and rail infrastructure contribute significantly to the market, as ferro-manganese improves mechanical properties, wear resistance, and toughness in steel alloys. Countries with large steel manufacturing capacities are driving global consumption and influencing production trends.

Insights from Ferro-Manganese Growth Forecast offer valuable projections of market trends, technological advancements, and regional consumption patterns. Forecasts help stakeholders identify opportunities for investment, anticipate changes in demand, and strategize production capacities. Technological innovations, including low-energy smelting, automation, and process optimization, are contributing to increased efficiency, reduced costs, and higher-quality ferro-manganese alloys.

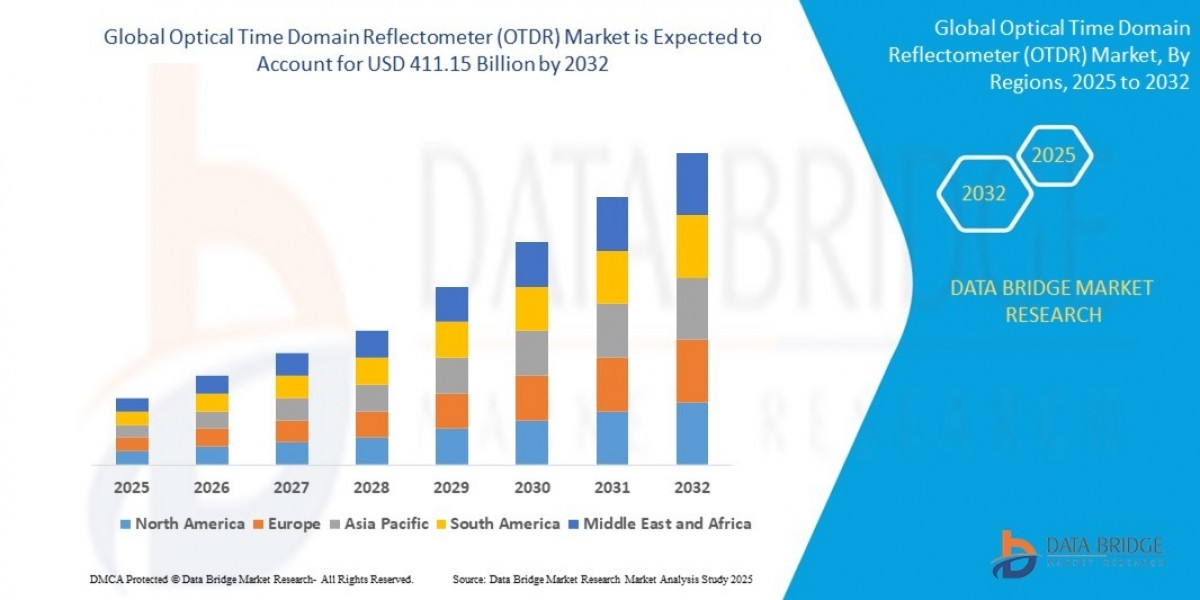

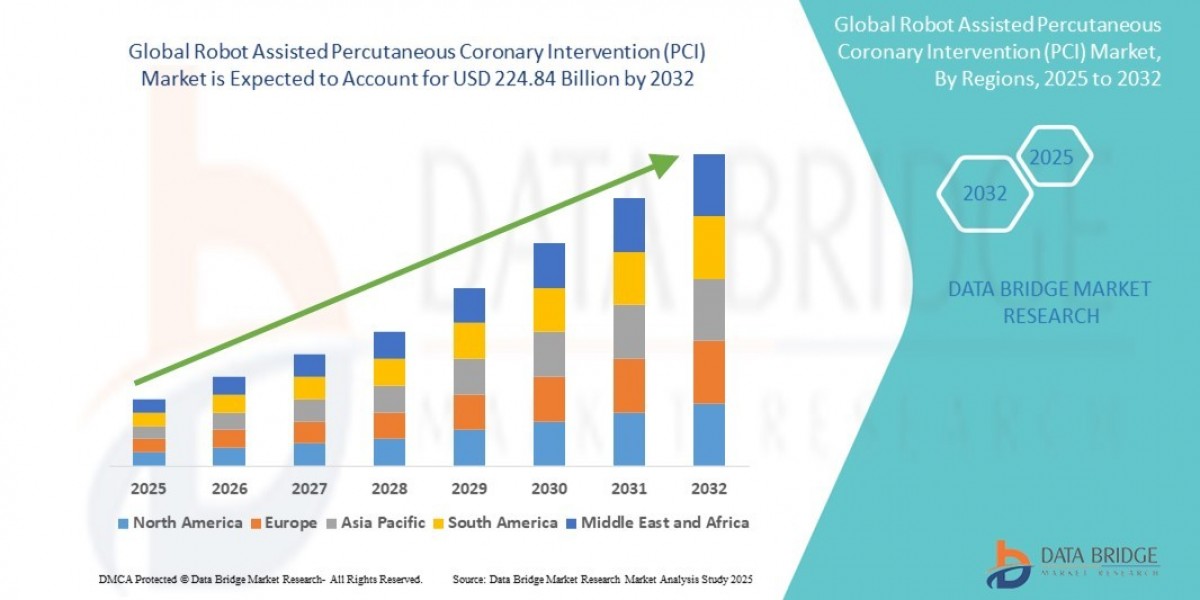

Regionally, Asia-Pacific is the largest consumer of ferro-manganese due to its dominant steel production industry, rapid urbanization, and infrastructure investments. North America and Europe maintain stable demand driven by industrial applications and automotive production. Latin America and the Middle East present growth opportunities as infrastructure development and industrial expansion accelerate.

Market growth is driven by increasing steel production, rising industrialization, and adoption of high-performance steel alloys. Ferro-manganese enhances steel durability, hardness, and toughness, making it indispensable in applications ranging from construction to heavy machinery. Advanced smelting technologies are further enabling manufacturers to produce high-quality ferro-manganese efficiently.

Challenges include volatility in raw material prices, energy-intensive production processes, and environmental regulations on emissions. Companies are addressing these issues by implementing energy-efficient technologies, adopting sustainable production practices, and investing in research to optimize resource usage. Strategic partnerships and supplier collaborations also help ensure consistent raw material supply and cost management.

The Ferro-Manganese Market indicates strong growth potential driven by infrastructure projects, urbanization, and technological advancements in steel production. Companies that invest in automation, regional expansion, and process innovation are well-positioned to benefit from rising global demand.

In conclusion, the Ferro-Manganese Market offers substantial growth opportunities. Rising steel production, industrial applications, and technological advancements in alloy production will continue to drive market expansion globally.

Related Report

Magneto Rheological Fluids Market

Hydrophobic Perlite Insulation Board Market