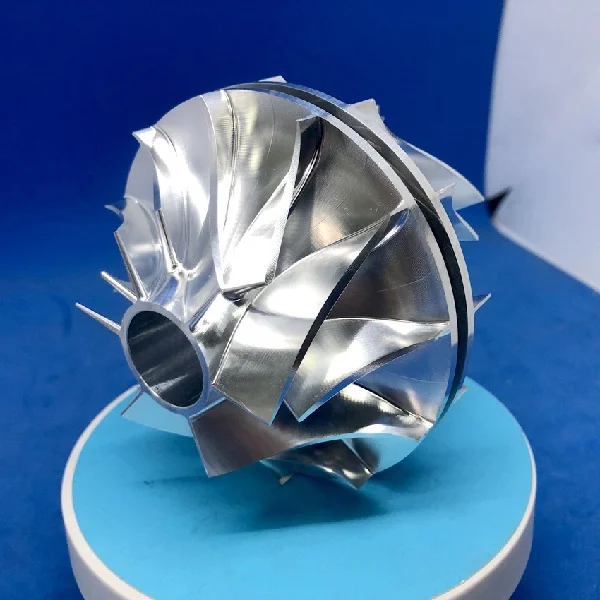

In the competitive world of mold manufacturing, achieving high precision, superior surface finish, and complex geometries is paramount. Traditional 3-axis or 4-axis machining often falls short when tackling intricate mold designs or high-performance components. That’s where 5-axis precision machining for molds comes into play, transforming the way manufacturers approach complexity, efficiency, and accuracy.

AICHI TECHNOLOGY, a global leader in advanced manufacturing solutions, leverages state-of-the-art 5-axis machining centers to produce molds with unmatched precision, consistency, and speed.

1. Understanding 5-Axis Precision Machining for Molds

5-axis machining allows simultaneous movement along five different axes, typically X, Y, Z, plus rotation on the A and B axes. This capability provides several advantages for mold production:

Enhanced geometric accuracy: Complex curves and undercuts are machined in a single setup.

Reduced setup time: Eliminates multiple repositioning steps, improving consistency.

Superior surface finish: Smooth contours reduce post-processing requirements.

Increased tool life: Optimized cutting angles minimize wear and tear.

For mold designers, this means greater design freedom, the ability to produce intricate features, and higher overall efficiency. AICHI TECHNOLOGY integrates these capabilities with precision calibration, ensuring molds meet exacting industrial standards.

2. Applications Across Mold Manufacturing Industries

5-axis precision machining is highly versatile, making it essential across a range of industries:

Automotive Industry

High-performance molds for injection-molded parts, engine components, and complex dashboards require tight tolerances and flawless surface finishes.

Aerospace and Defense

Lightweight structural components and precision molds for composite materials demand intricate geometries and repeatable accuracy.

Medical Device Manufacturing

Injection molds for prosthetics, surgical instruments, and plastic medical parts benefit from cleanroom-compatible machining and micron-level precision.

Consumer Electronics

Housings and enclosures for devices like smartphones or laptops demand both aesthetic appeal and functional precision, achievable only with advanced 5-axis technology.

3. How AICHI TECHNOLOGY Leads the Industry

AICHI TECHNOLOGY has positioned itself as a trusted partner for precision mold manufacturing, combining cutting-edge machinery, experienced engineers, and customized process solutions.

Key Advantages Include:

Integrated CAD/CAM Systems: Seamless digital workflow from design to finished mold.

High-Speed, Multi-Axis Machining Centers: Ensuring tight tolerances and surface consistency.

Expertise in Diverse Materials: Aluminum, stainless steel, copper alloys, and advanced composites.

Custom Tooling Solutions: Optimized for mold complexity and material properties.

Quality Control and Inspection: Inline measurement ensures each mold meets ISO 9001 and other international standards.

By combining hardware, software, and process innovation, AICHI TECHNOLOGY delivers molds that consistently exceed client expectations.

4. Benefits for B2B Clients

For manufacturers and industrial partners, investing in 5-axis precision machining with AICHI TECHNOLOGY provides measurable advantages:

Faster Time-to-Market: Reduce production cycles without compromising quality.

Cost Efficiency: Minimize rework and scrap with precise machining.

Design Flexibility: Enable more complex mold geometries and functional features.

Global Compliance: Molds adhere to international tolerance and safety standards.

Clients ranging from automotive suppliers to high-tech electronics companies rely on AICHI TECHNOLOGY for repeatable, scalable, and precision-driven mold production.

5. Advanced Capabilities: Beyond Machining

AICHI TECHNOLOGY integrates process optimization, simulation, and predictive maintenance into its 5-axis machining solutions. Advanced software allows:

Real-time toolpath simulation

Predictive wear analysis

Automated adjustment for thermal expansion

Seamless integration with downstream finishing or assembly operations

This approach minimizes downtime, reduces waste, and ensures molds maintain peak performance from prototype to full-scale production.

Conclusion: Precision, Performance, and Partnership

In modern mold manufacturing, 5-axis precision machining is no longer optional—it’s essential. AICHI TECHNOLOGY combines advanced machining technology, experienced engineering teams, and comprehensive quality assurance to deliver molds that meet the most demanding industrial standards.

By partnering with AICHI TECHNOLOGY, manufacturers gain access to innovative solutions, optimized production efficiency, and molds that drive product excellence. For companies seeking to balance precision, cost-effectiveness, and design flexibility, AICHI TECHNOLOGY stands as a reliable global partner.