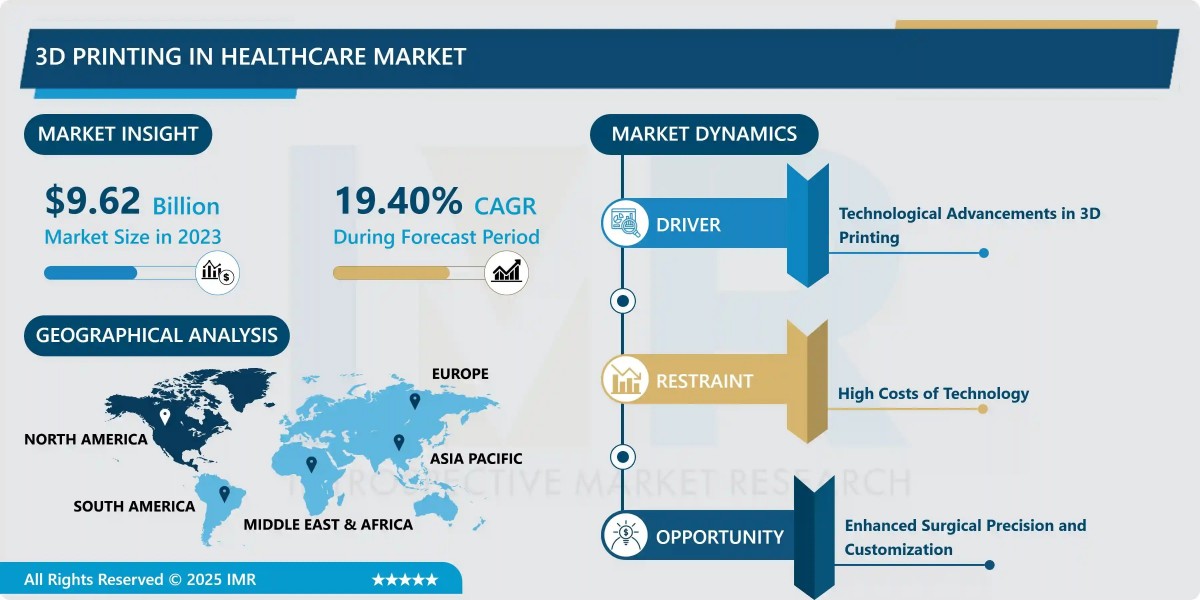

Introspective Market Research, a premier provider of healthcare and technology market intelligence, today announced the release of its comprehensive report on the Global 3D Printing in Healthcare Market. This transformative sector, which enables the precise creation of anatomical models, custom implants, and prosthetic devices, was valued at USD 9.62 Billion in 2023. The confluence of advanced materials, rising surgical precision requirements, and major investment is projected to catapult the market to USD 47.45 Billion by 2032, achieving an exceptional CAGR of 19.40% during the 2024–2032 forecast period.

The market’s phenomenal growth pace is primarily fueled by technological advancements, particularly in the creation of individualized medical devices and the revolutionary possibilities of bioprinting for regenerative medicine.

Click Here to Request Sample Report: https://www.google.com/search?q=https://introspectivemarketresearch.com/request/17944

Quick Insights: 3D Printing in Healthcare Market (2024–2032)

Metric | Insight |

2023 Market Valuation | USD 9.62 Billion |

Projected 2032 Valuation | USD 47.45 Billion |

CAGR (2024-2032) | 19.40% |

Dominant Application | Medical Implants (Due to demand for patient-specific orthopedic and dental devices) |

Dominant Technology | Stereo Lithography (SL) (Known for high resolution and accuracy) |

Leading Regional Market | North America (Strong R&D spending and robust healthcare infrastructure) |

Key Market Driver | Technological Advancements in 3D Printing |

Key Opportunity | Expansion of Bioprinting and Personalized Medicine |

Segmentation Analysis: Implants Lead the Charge, SL Technology Dominates

The core of the 3D Printing in Healthcare market lies in its ability to offer customization far beyond traditional manufacturing limits.

- Application Dominance: The Medical Implants segment currently holds the largest market share. This dominance is driven by orthopedic, dental, and craniomaxillofacial (CMF) applications, where patient-specific fit translates directly into reduced surgical time, faster recovery, and improved patient outcomes. The demand for lightweight, custom-fitted Prosthetics and Wearable Devices also remains a strong growth component.

- Technology Breakdown: By technology, Stereo Lithography (SL) is anticipated to dominate the market. SL remains a preferred choice for producing detailed anatomical models and molds due to its high resolution and precision, making it essential for pre-operative planning and educational purposes. Other technologies, including Deposition Modeling and Electron Beam Melting, are seeing increased use, particularly with metal alloys for high-strength implants.

How is Bioprinting Pushing the Boundaries of Regenerative Medicine?

The most significant long-term opportunity shaping the market is the rapid Expansion of Bioprinting Applications. Bioprinting uses specialized bioinks—mixtures of living cells and biocompatible materials—to fabricate functional tissue and organ structures layer-by-layer.

This cutting-edge trend offers multiple revolutionary pathways:

- Organ Regeneration: It promises to solve the critical organ donor deficit by potentially creating functional, patient-matched organs for transplantation, dramatically minimizing rejection risk.

- Disease Modeling: 3D-printed human tissues can serve as highly accurate models for drug discovery and toxicology testing, replacing traditional, less-predictive animal models.

- Personalized Therapy: The ability to print tissues derived from a patient’s own cells is the ultimate step toward regenerative, personalized medicine.

Expert Insight: North America’s Innovation Ecosystem

"North America is set to maintain its leadership position, not just because of its high healthcare expenditure, but because of its mature innovation ecosystem," states Mr. Rohan Sharma, Principal Consultant at Precedence Research. "The region benefits from a robust regulatory framework that, while stringent, fosters safe and rapid adoption of advanced technologies. The critical mass of specialized R&D centers, venture capital funding, and strategic collaborations between tech firms and major university hospitals ensures that advancements in bioprinting and patient-specific device creation move quickly from the lab bench to clinical application."

Breakthroughs and Strategic Moves in Precision Manufacturing

Leading companies are focusing on enhancing the speed, material diversity, and accessibility of 3D printing solutions:

- Focus on Materials: Significant investment is being poured into developing new medical-grade polymers, ceramics, and bioinks that are fully biocompatible and biodegradable, paving the way for temporary internal scaffolds that dissolve as the body heals.

- Software Integration: Key players are integrating sophisticated AI-driven software that streamlines the workflow from patient scan (MRI/CT) to final printed product, drastically reducing design time for custom implants and surgical guides. This shift is democratizing access to complex 3D printing capabilities.

Challenges: Addressing High Costs and Regulatory Hurdles

Despite the clear benefits, the market faces two primary challenges: the High Initial Cost of Technology and complex Regulatory Hurdles. The initial investment required for high-end 3D printing equipment (like Electron Beam Melting machines) and specialized raw materials can be prohibitive for smaller hospitals and research institutions. Furthermore, the regulatory environment for patient-specific implants and the nascent field of bioprinted organs remains complex, requiring significant time and financial resources to achieve approvals.

Case Study: Revolutionizing Craniomaxillofacial Surgery

A leading CMF surgical center implemented 3D printing for 90% of its complex facial trauma cases. By generating patient-specific anatomical models and custom titanium implants pre-surgery, the team was able to reduce average operative time by 25%. The custom implants resulted in fewer post-operative complications and significantly improved aesthetic and functional patient outcomes, demonstrating a clear clinical and economic advantage over 'off-the-shelf' solutions.

Call to Action

[Click Here to Request Sample Report]

About Introspective Market Research

Introspective Market Research (IMR) is a trusted provider of comprehensive market intelligence, offering in-depth insights into global industry trends, competitive landscapes, and growth opportunities. Our reports empower businesses to make informed, strategic decisions that accelerate growth and maximize value across diverse sectors.

Contact: Introspective Market Research Phone: +91-74101-03736

Email: sales@introspectivemarketresearch.com

Website: https://introspectivemarketresearch.com/