In the evolving world of manufacturing, the automation of assembly processes is becoming a strategic imperative. The comprehensive forecast for the Assembly Automation Market signals a major shift: as manufacturers seek higher throughput, greater flexibility, lower costs and smarter operations, the landscape is rapidly changing. According to a recent study, the market is set to grow substantially in the coming years. For full details see the full report here: Assembly Automation Market Forecast.

Surge in Demand: What’s Driving the Growth?

Several major factors are converging to drive demand for automated assembly solutions. First, manufacturers across industries—automotive, electronics, consumer goods, medical devices—are under pressure to reduce cycle times, improve quality and increase output. Manual assembly lines are increasingly unable to meet these demands. Second, labour costs and labour shortages in many regions are compelling manufacturers to seek automation to maintain competitiveness. Third, advances in robotics, machine vision, sensor technologies and AI are unlocking new capabilities: flexible assembly lines, collaborative robots (cobots), real-time monitoring and adaptive systems. Fourth, the push toward Industry 4.0 and smart manufacturing is creating incentives and funding for upgrades and retrofits; assembly automation is a key pillar. Fifth, emerging markets are coming online with new plants, and established plants are undergoing modernization, further boosting demand for automated assembly systems.

Market Outlook: The Numbers

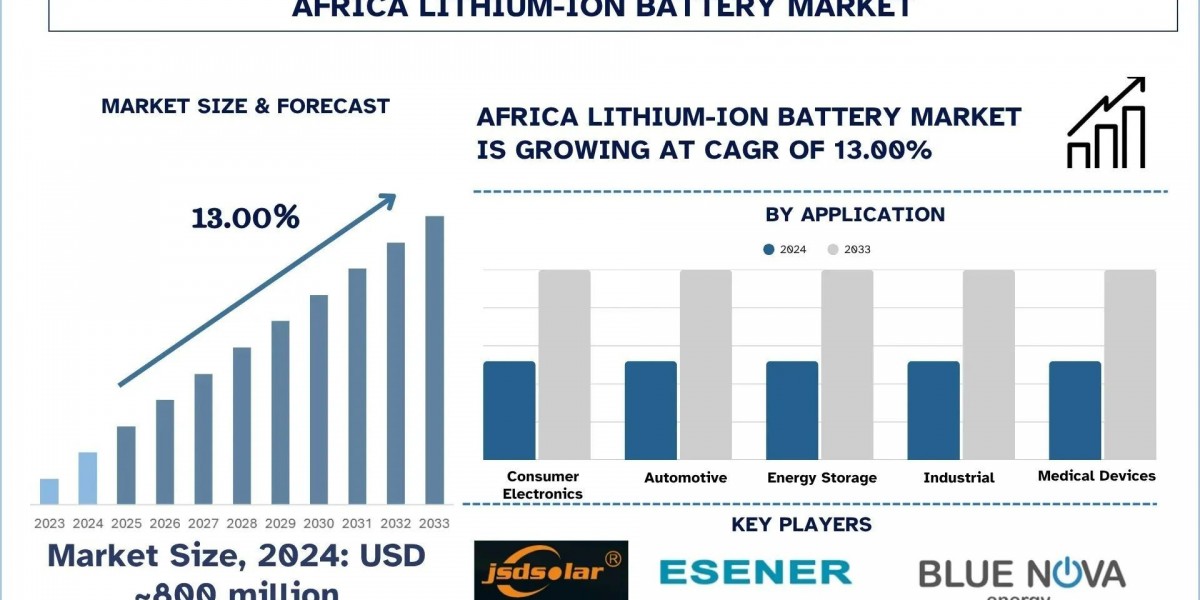

According to the referenced forecast, the assembly automation market is expected to grow at a strong pace. The current base (mid-2020s) is already substantial and the projection looks bold. The report suggests that the market will achieve a compound annual growth rate (CAGR) of approximately 13% over the forecast period. The end-value is projected to be in the hundreds of billions of USD. In short: this isn’t incremental growth—it’s transformational. What this means is that companies in the automation ecosystem—from robot manufacturers, system integrators, sensor providers, drive and control vendors, to software‐analytics firms—have a large window of opportunity to capture value.

Segmentation and Market Dynamics

To understand the market deeply, segmentation matters. We can look at the market by:

Component type: hardware (robots, actuators, conveyors, inspection systems), software (control, vision, analytics), services (installation, maintenance, integration)

Automation type: fixed automation, flexible automation, lean automation, robotic automation

Application/end-use industry: automotive, electronics & semiconductors, consumer goods, healthcare/medical devices, aerospace, others

Geography: mature markets (North America, Europe, Japan) and high-growth markets (Asia-Pacific, Latin America, Middle East & Africa)

Some interesting trends include the rise of robot automation equipment within assembly lines—which is expected to capture a large share, given robots are becoming more affordable and flexible. Also, flexible and lean automation are gaining favour over rigid fixed systems, as manufacturers need to switch product variants rapidly and scale operations up or down. In terms of industries, automotive continues to dominate given its long history of automation, but electronics and medical device assembly are catching up thanks to miniaturisation, more complex assemblies and higher quality demands.

Regional Insights

While developed regions will continue to hold significant share, the fastest growth is likely to come from Asia-Pacific regions where manufacturing expansion is robust. Countries such as China, India, Southeast Asian nations are setting up new plants or upgrading existing ones, often with government support or incentives for advanced manufacturing. Also, global supply chain shifts (reshoring, near-shoring) and rising labour cost in previously low‐cost countries are pushing automation. Manufacturers operating in India, for example, may find that investing in assembly automation can help leapfrog legacy infrastructure and make locally produced goods globally competitive.

Strategic Implications for Stakeholders

For automation vendors, the forecast underlines the need to invest in product innovation, modularity, ease of deployment, connectivity and service capabilities. Delivering turnkey solutions rather than just components will be critical. For manufacturers, the message is clear: automation is no longer optional—it’s strategic. The time to evaluate the ROI, pilot flexible assembly systems and assess integration of software analytics is now. For integrators and service firms, the opportunity lies in retrofits, upgrades, maintenance contracts and lifecycle services. For investors, the high-growth nature of the segment suggests attractive upside, particularly in companies offering best-in-class robotics, vision systems, AI enabled control and integration platforms.

Challenges & Risk Factors

Growth prospects aside, there are challenges. High upfront capital costs, integration complexity, workforce skill gaps (technicians, automation engineers), interoperability issues between legacy and new systems, cybersecurity and data privacy concerns are real headwinds. Market cycles (economic downturns) can delay investment; some industries may prioritise cost-cutting over upgrades. Moreover, automation technology evolves quickly, so vendors and manufacturers need to future-proof installations.

Final Thoughts

In summary, the Assembly Automation Market is charting a robust growth trajectory. The convergence of manufacturing modernization, robotics and digital transformation is unlocking vast opportunities. Whether you’re a manufacturer deliberating automation, a vendor building solutions or an investor scanning for winners, this market deserves attention. As the forecast shows, the next decade is poised to transform assembly lines from static, manual operations into smart, agile, highly automated systems. Embracing that transformation early could provide a competitive advantage in both performance and cost.

More Related Report

Commercial Vehicle Telematics Market Size

Electric Cargo Bikes Market Size