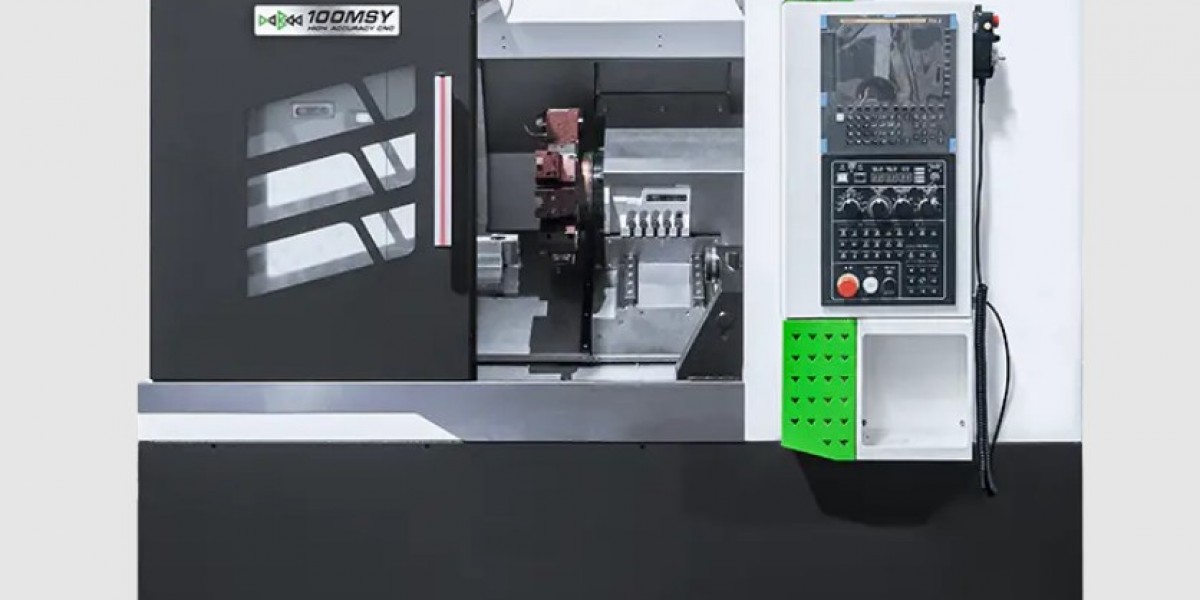

A CNC slant bed lathe is a type of lathe designed with a slanted bed structure, which provides improved rigidity and chip evacuation during machining. The slanted configuration allows the cutting forces to be distributed more efficiently, reducing vibration and enhancing precision.

CNC technology enables operators to program complex machining processes, including turning, threading, and drilling, with minimal manual intervention. These machines are suitable for machining a wide range of materials, from steel to aluminum alloys. The slant bed design also makes it easier to handle longer workpieces, as gravity assists in positioning and support. CNC slant bed lathes often include features such as automatic tool changers, programmable spindle speeds, and advanced control software, which contribute to consistent production and reduced setup times.

The combination of structural design and computerized control allows for higher accuracy in creating components with specific tolerances. These lathes are commonly used in industries such as automotive, aerospace, and machinery manufacturing. Proper maintenance, including inspection of guides and lubrication, is essential to preserve the machine’s performance. By integrating modern CNC technology with the slant bed design, these lathes provide a balanced solution for efficient and precise metalworking.