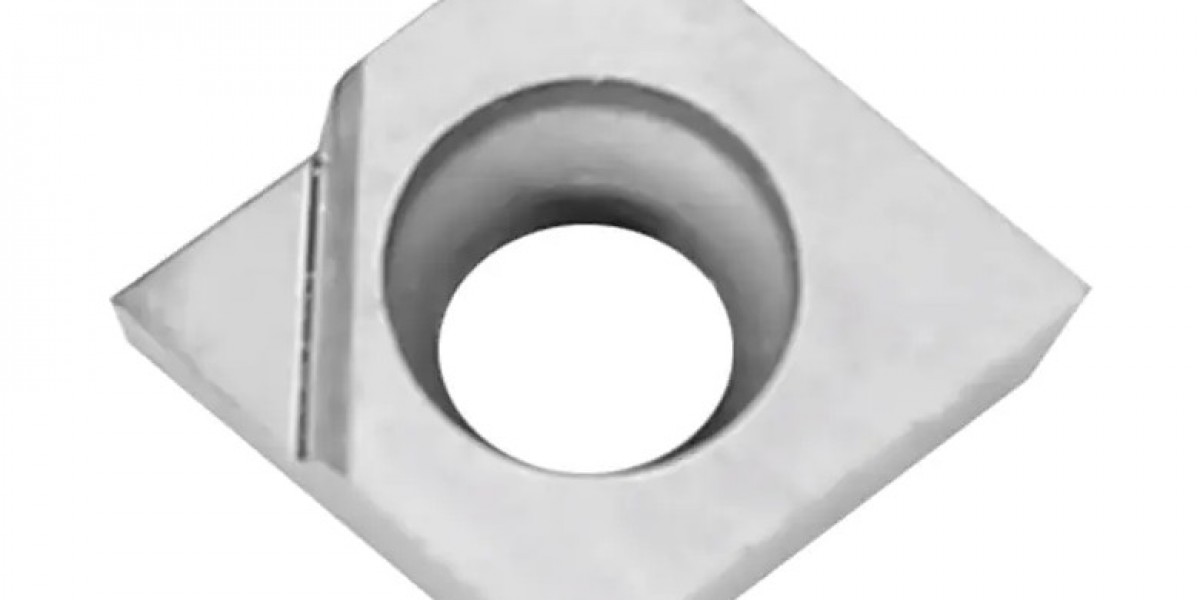

The Indexable Insert has become indispensable in modern industrial machining, allowing tool users to replace only the worn cutting edge instead of the entire tool. This practical design ensures consistent cutting results and reduces overall production costs. Our factory manufactures a variety of inserts used in milling, turning, drilling, and shaping operations, all of which are made from carefully selected tungsten carbide materials.

The precision of each insert lies in its design geometry. Properly engineered rake angles and chipbreakers can significantly improve chip evacuation, reduce heat generation, and stabilize the cutting process. By combining high hardness with adequate toughness, our inserts are capable of maintaining sharpness under demanding conditions, including high-speed and interrupted cuts.

Coating technology further strengthens the insert’s performance. PVD and CVD coatings are applied to create a protective layer that resists oxidation and thermal deformation. Each coated insert undergoes adhesion and thickness testing to ensure consistent coverage and durability. These coatings help extend tool life and maintain surface finish quality, especially in automated production lines.

Our inserts are widely applied in manufacturing industries including automotive, aerospace, mold making, and mining. Clients who work with complex materials rely on our engineering team to recommend suitable insert grades and edge profiles. For specific applications, we can design non-standard shapes according to technical drawings or sample requirements.

We also emphasize environmental and cost efficiency. The replaceable edge system reduces tool waste and material consumption. By providing reliable and stable inserts, we help factories maintain smooth operations with minimal downtime. Each product reflects our commitment to practical innovation and long-term partnership with users worldwide.