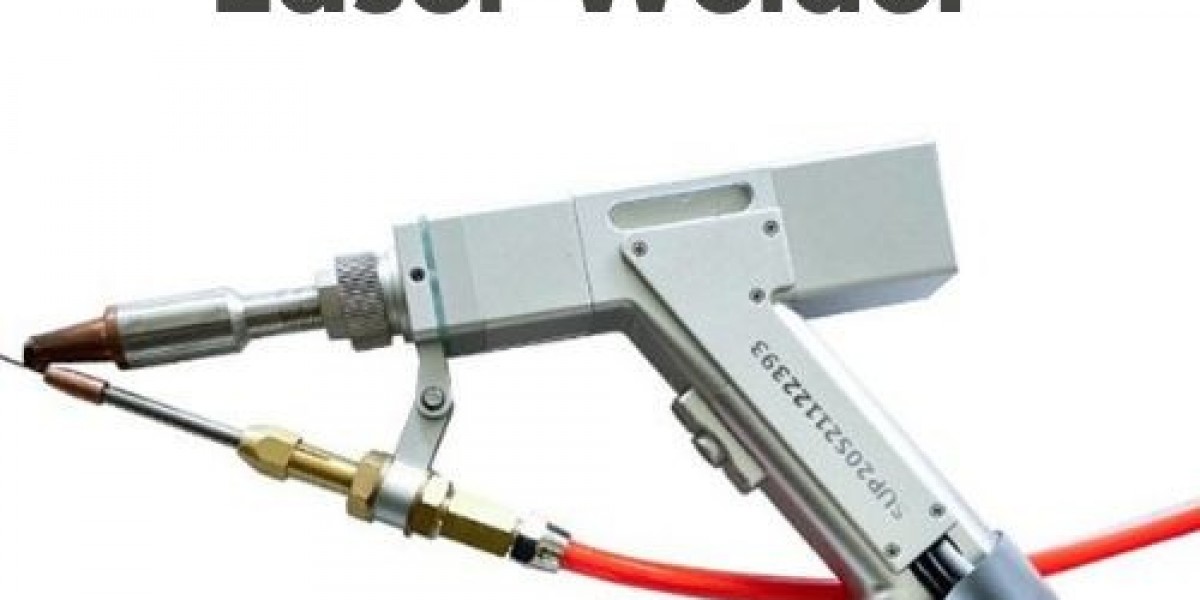

In modern manufacturing, efficiency, accuracy, and ease of use are crucial. Traditional welding methods often fall short in precision and flexibility—this is where the handheld metal laser welder is transforming the industry. Designed for both small workshops and large-scale production, this advanced tool delivers smooth, durable welds with remarkable speed and minimal distortion.

Redefining Modern Welding Technology

The handheld metal laser welder represents a leap forward in fabrication technology. Unlike conventional TIG or MIG welding, it uses concentrated laser energy to fuse metals with exceptional accuracy. This process minimizes thermal distortion and post-processing work while improving the overall finish. Whether for stainless steel, aluminum, or carbon steel, the results are consistently strong and visually flawless.

LaserChina, a trusted name in industrial laser solutions, has refined this technology to meet the needs of modern manufacturers. Their systems are designed to make high-quality welding accessible, reliable, and remarkably easy to master.

Ease of Operation for Every Skill Level

One of the standout advantages of LaserChina’s welding equipment is user-friendliness. Operators don’t need years of experience to achieve professional results. The ergonomic design of the handheld gun, combined with intuitive controls, allows users to perform complex welds comfortably and safely. This convenience makes it ideal for workshops looking to increase productivity without extensive training or setup time.

Efficiency that Boosts Productivity

Speed and precision define the handheld metal laser welder. It can work up to four times faster than traditional methods while producing a cleaner, more consistent result. The high beam quality ensures deep penetration and minimal heat impact, reducing material waste and rework. For manufacturers aiming to streamline operations, this translates to faster turnaround and greater cost savings.

Applications Across Diverse Industries

From automotive repairs to custom metal fabrication, the versatility of laser welding makes it suitable for a wide range of applications. Builders, artisans, and engineers all benefit from its ability to join intricate metal components with ease. The technology is also gaining traction in aerospace, electronics, and jewelry sectors—industries where precision and visual appeal are equally important.

Why Choose LaserChina

With years of expertise in laser innovation, LaserChina continues to lead the market with reliable and high-performing equipment. Each handheld system is engineered for stability, longevity, and optimal output. Backed by professional support and customization options, LaserChina ensures that businesses get the right welding solution for their specific needs.

Final Thoughts

The rise of the handheld metal laser welder marks a turning point in the world of metal fabrication. It combines cutting-edge performance with the convenience of portability, empowering manufacturers to produce superior results with less effort. For anyone seeking a balance of innovation, precision, and efficiency, LaserChina delivers a welding solution that defines the future of metalworking.