Waste Processing Equipment includes machinery designed to handle and process various types of waste materials, including municipal, industrial, and hazardous waste. Shredder blades are a critical component of this equipment, enabling effective waste reduction and recycling. The growing emphasis on sustainable waste management practices and the need for efficient processing solutions are driving the demand for advanced waste processing equipment. As regulations around waste disposal tighten, the market for shredder blades and associated equipment is expected to expand.

Shredder blades are essential components in industrial shredding machines used for processing various materials such as plastics, metals, paper, and e-waste. The global shredder blades market is growing rapidly, driven by increasing recycling initiatives, environmental regulations, and demand for efficient waste management solutions. Industries such as manufacturing, automotive, and municipal waste management rely heavily on shredder blades to reduce material size for recycling, disposal, and energy recovery. The performance and durability of shredder blades directly impact operational efficiency and cost-effectiveness.

Market Drivers

The market is primarily driven by the global emphasis on sustainable waste management and circular economy initiatives. Growing concerns about environmental pollution and the need for recycling of plastics, metals, and e-waste are boosting demand for shredding equipment. Technological advancements in blade design, material composition, and heat treatment processes have improved the lifespan and cutting efficiency of shredder blades. Additionally, the rise of automated shredding systems and high-capacity industrial shredders has further increased the need for durable and high-performance blades.

Product Segmentation

Shredder blades are categorized based on design, material, and application. Common types include straight blades, serrated blades, hook blades, and custom-designed blades tailored for specific shredding requirements. Materials used for manufacturing shredder blades include high-speed steel, alloy steel, and tool steel, often enhanced with coatings for wear resistance. Applications span multiple industries, including plastic recycling, metal processing, paper recycling, e-waste management, and wood processing. The versatility and adaptability of shredder blades make them indispensable in modern recycling and waste management operations.

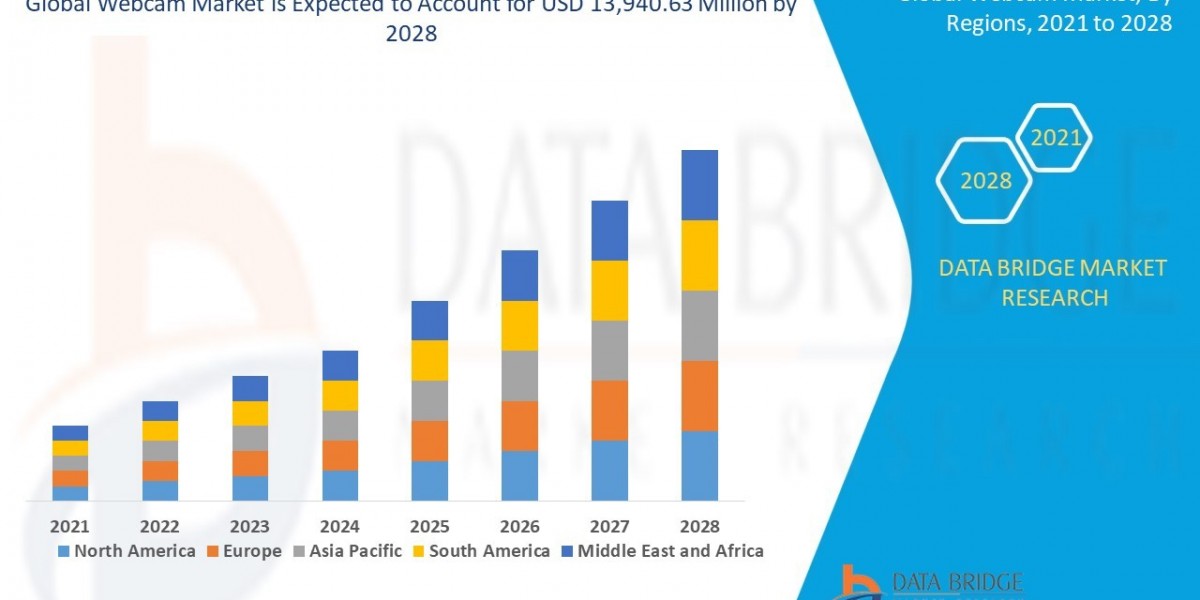

Regional Insights

North America and Europe are significant markets due to stringent environmental regulations and widespread adoption of recycling initiatives. Asia-Pacific is emerging as a key growth region, driven by industrialization, urbanization, and government policies promoting waste reduction and recycling. Manufacturers are expanding production facilities in emerging economies to meet local demand and reduce lead times. Strategic collaborations with recycling companies, government projects, and industrial players are enhancing market penetration across regions.

Competitive Landscape

The market is moderately fragmented, with several global and regional players competing on the basis of quality, durability, and technological innovation. Companies are focusing on R&D to improve blade performance, reduce maintenance requirements, and develop specialized solutions for high-capacity shredding operations. Market players are also emphasizing aftermarket services, including blade sharpening, replacement, and maintenance programs to increase customer satisfaction and loyalty.

Challenges in the Market

High wear and tear, operational downtime, and replacement costs are key challenges for the shredder blades market. Additionally, variations in raw material prices can impact production costs. To address these issues, manufacturers are investing in advanced metallurgical processes, heat treatment technologies, and durable coatings that extend blade life and enhance cutting efficiency.

Future Outlook

The shredder blades market is projected to witness continued growth as industries increasingly adopt sustainable and efficient waste management practices. Innovations in blade design, integration with automated shredding systems, and development of multi-material shredding solutions will shape the future market landscape. Increasing focus on recycling, waste-to-energy projects, and regulatory compliance will further drive demand for high-performance shredder blades globally.

FAQs

Q1: What are shredder blades used for?

Shredder blades are used in industrial shredders to cut, slice, or reduce materials such as plastics, metals, paper, and e-waste into smaller sizes.

Q2: What materials are shredder blades made from?

They are commonly made from high-speed steel, alloy steel, or tool steel, often with coatings for enhanced durability and wear resistance.

Q3: How do manufacturers improve shredder blade longevity?

Advanced heat treatments, special coatings, and precision design enhancements help extend blade life and reduce maintenance frequency.

More Related Reports: