The global Robotic End-Effector Market has been experiencing significant growth in recent years, driven by advancements in automation technologies across various industries. In 2022, the market size was estimated at USD 3.25 billion, and it is projected to grow from USD 3.57 billion in 2023 to USD 8.32 billion by 2032, representing a Compound Annual Growth Rate (CAGR) of 9.86% from 2024 to 2032.

What is a Robotic End-Effector?

A robotic end-effector refers to the device attached to the end of a robotic arm that interacts with the environment to perform tasks. These tools are crucial for executing specific functions like gripping, welding, cutting, or even more specialized tasks such as assembly or inspection. In industrial robots, end-effectors are highly customized to match the needs of the application, enhancing productivity and precision.

Get FREE Sample Report:

https://www.marketresearchfuture.com/sample_request/8571

Key Drivers of Market Growth

- Automation in Manufacturing: One of the primary factors driving the growth of the robotic end-effector market is the increasing adoption of automation in manufacturing processes. Industries such as automotive, electronics, consumer goods, and food processing are integrating robotic systems to improve efficiency, reduce costs, and increase product quality. As robots perform more complex tasks, the demand for advanced end-effectors grows.

- Rising Labor Costs: Labor shortages and rising labor costs are pushing industries toward automation solutions, including the use of robotic arms and their respective end-effectors. By automating tasks such as assembly, packaging, and quality control, companies can not only reduce operational costs but also improve accuracy and speed.

- Technological Advancements: Technological innovations in sensor technology, AI, and machine learning are allowing robotic end-effectors to perform a broader range of tasks more efficiently. For example, advancements in soft robotics are providing robots with more dexterity and the ability to handle delicate or irregularly shaped objects, which further increases their application in various industries.

- Growth of the E-Commerce Sector: The rise in e-commerce has led to increased demand for automated systems for sorting, packaging, and shipping products. Robotic end-effectors are central to streamlining warehouse and distribution operations, allowing for faster order fulfillment and reducing errors in packaging and sorting.

- Collaborative Robots (Cobots): The rise of collaborative robots, or cobots, is also fueling the demand for robotic end-effectors. Cobots are designed to work alongside human workers and are equipped with end-effectors that can perform specific tasks such as assembly, inspection, or material handling with greater precision and safety.

Market Segmentation

The robotic end-effector market is divided into several segments based on type, end-user industry, and region.

- By Type:

- Grippers: Grippers are the most common type of end-effector, used primarily for picking up, holding, and manipulating objects. These can be mechanical, vacuum-based, or magnetic.

- Welding Torches: Used in robotic systems for welding applications, these end-effectors are vital in the automotive and manufacturing industries.

- Suction Cups: These are commonly used in material handling applications, particularly for picking up flat or smooth objects.

- Drills and Cutters: Essential in industries like aerospace and construction, these end-effectors are used for precision drilling and cutting tasks.

- By End-User Industry:

- Automotive: Robotic end-effectors are used in assembly lines for tasks such as welding, painting, and assembling components.

- Electronics: In electronics, robotic end-effectors are used for component placement, testing, and assembly in high-precision environments.

- Food & Beverage: These end-effectors are employed in food packaging, sorting, and material handling tasks.

- Healthcare & Pharmaceuticals: Robotic end-effectors are used for drug dispensing, packaging, and even in surgical applications, where precision is crucial.

Regional Outlook

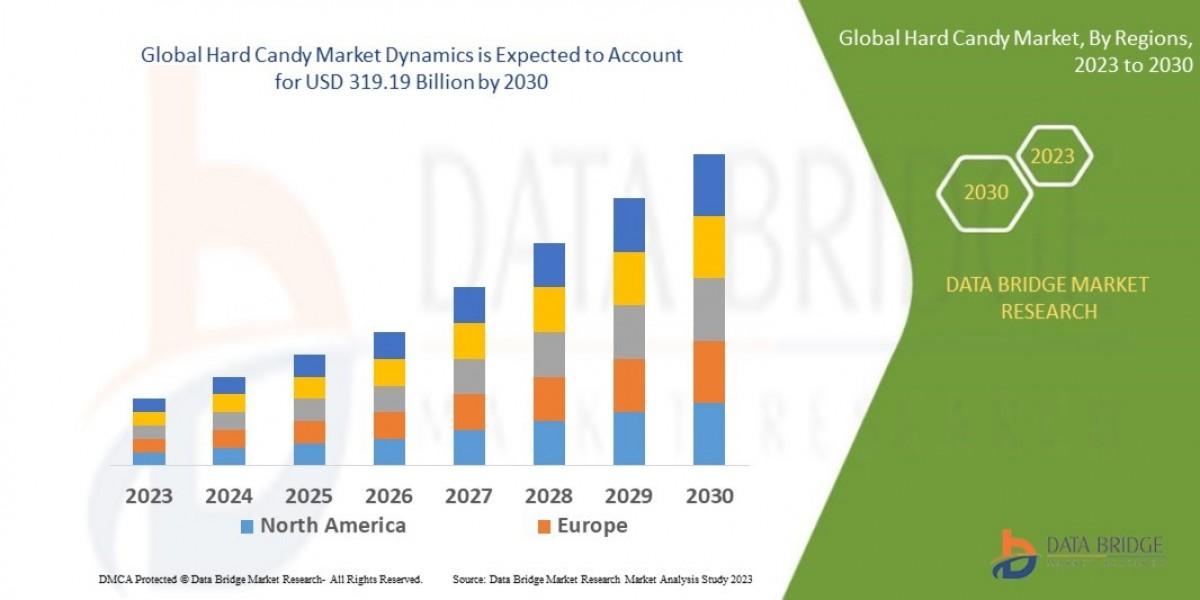

The global robotic end-effector market is witnessing varied growth trends across different regions:

- North America: The North American market is expected to dominate during the forecast period, driven by the high demand for automation in industries such as automotive, electronics, and food processing. The presence of major players and technological advancements in robotics also contribute to the market’s growth in this region.

- Europe: Europe is also witnessing substantial growth, especially in countries like Germany, the UK, and France, where the automotive and manufacturing sectors are heavily investing in robotic solutions.

- Asia-Pacific: The Asia-Pacific region is expected to witness the highest growth rate, with countries like China, Japan, and South Korea leading in robotics adoption. The rapid industrialization and the increasing trend of automation in sectors such as electronics and automotive are major contributors to market growth in this region.

- Rest of the World: Growth in the rest of the world is expected to be moderate, but regions like the Middle East and Latin America are increasingly adopting robotic technologies in industries such as oil & gas and manufacturing.

Challenges

While the market is on a growth trajectory, several challenges remain:

- High Initial Investment: The cost of implementing robotic systems, including end-effectors, can be prohibitive, particularly for small and medium-sized enterprises (SMEs).

- Skill Gap: The lack of skilled workers in robotics and automation technology may slow down the pace of adoption, especially in emerging markets.

- Complexity in Integration: Integrating robotic end-effectors into existing production lines or systems can be complex, requiring significant customization and technical expertise.

Future Outlook

Looking ahead, the Robotic End-Effector Market is poised for continued growth, fueled by technological advancements and increasing automation in various sectors. By 2032, the market is expected to reach USD 8.32 billion, with a CAGR of 9.86%. As industries continue to embrace automation, the demand for robotic systems and their corresponding end-effectors will only intensify, creating opportunities for innovation, efficiency, and cost reduction across the global supply chain.