In today’s competitive manufacturing world, global brands are under constant pressure to deliver high-quality products faster, at scale, and with precision. This is where leading Die Casting Manufacturers play a crucial role. From automotive giants to consumer electronics companies, businesses across industries rely on die casting to produce strong, lightweight, and cost-effective components. But what makes these manufacturers so sought after, especially by global players? Let’s dive deeper into why they are the preferred choice—and why their expertise matters.

Precision Meets Consistency

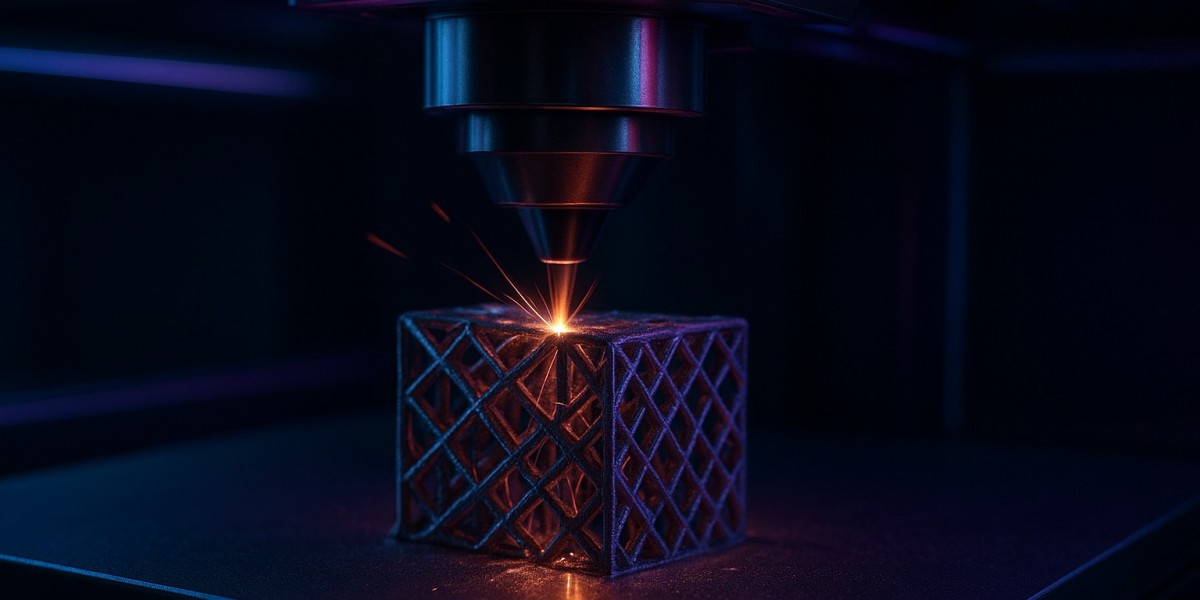

One of the biggest reasons global brands partner with top Die Casting Manufacturers is precision. Die casting is not just about pouring molten metal into a mold; it’s about creating parts that meet exact specifications—again and again. Leading manufacturers invest heavily in advanced machinery, automation, and skilled technicians to ensure every part comes out perfect, whether it’s the first piece or the ten-thousandth.

This precision is particularly important in industries like automotive and aerospace, where even the smallest error can compromise safety or performance. By working with experienced manufacturers, brands gain peace of mind knowing their components will perform flawlessly.

The Power of Zinc Die Casting

While aluminium often gets the spotlight, Zinc Die Casting is becoming increasingly popular among global brands. Zinc offers several advantages—superior strength, excellent surface finish, and the ability to produce thinner walls without sacrificing durability. These properties make zinc a top choice for intricate parts, like connectors, brackets, and housings.

Leading manufacturers understand these benefits and offer dedicated zinc die casting solutions tailored to their clients’ needs. They know which alloy to use, how to optimize the mold design, and how to keep production efficient without compromising quality.

Cost-Effectiveness at Scale

Scaling production is one of the biggest challenges for global brands. The more parts you need, the more critical it becomes to keep costs under control. Top Die Casting Manufacturers have mastered the art of balancing quality and cost-effectiveness. They optimize cycle times, minimize material wastage, and leverage high-volume production capabilities to offer competitive pricing—without cutting corners.

This combination of efficiency and reliability allows brands to maintain profit margins while still delivering top-tier products to their customers.

Innovation and Collaboration

Another reason global brands trust leading manufacturers is their focus on innovation. The best in the industry don’t just deliver parts—they collaborate with their clients early in the design stage. They suggest improvements, recommend materials (including when Zinc Die Casting might outperform other methods), and help streamline production.

This kind of partnership is invaluable for companies looking to reduce time-to-market and stay ahead of competitors. By involving manufacturers early in the process, brands avoid costly redesigns and benefit from practical, real-world manufacturing insights.

Commitment to Quality and Sustainability

Global brands are under increasing pressure to adopt sustainable practices. Leading Die Casting Manufacturers are stepping up by reducing energy consumption, recycling scrap metal, and adhering to strict quality and environmental standards. This not only helps brands meet compliance requirements but also supports their ESG (Environmental, Social, and Governance) goals.

Final Thoughts

Global brands prefer working with top Die Casting Manufacturers because they deliver precision, scalability, innovation, and cost-efficiency—all under one roof. With expertise in both aluminium and Zinc Die Casting, these manufacturers provide solutions that meet the demanding needs of modern industries.

If you’re a business looking to streamline production and ensure your components meet world-class standards, partnering with a trusted die casting expert could be one of the smartest moves you make.