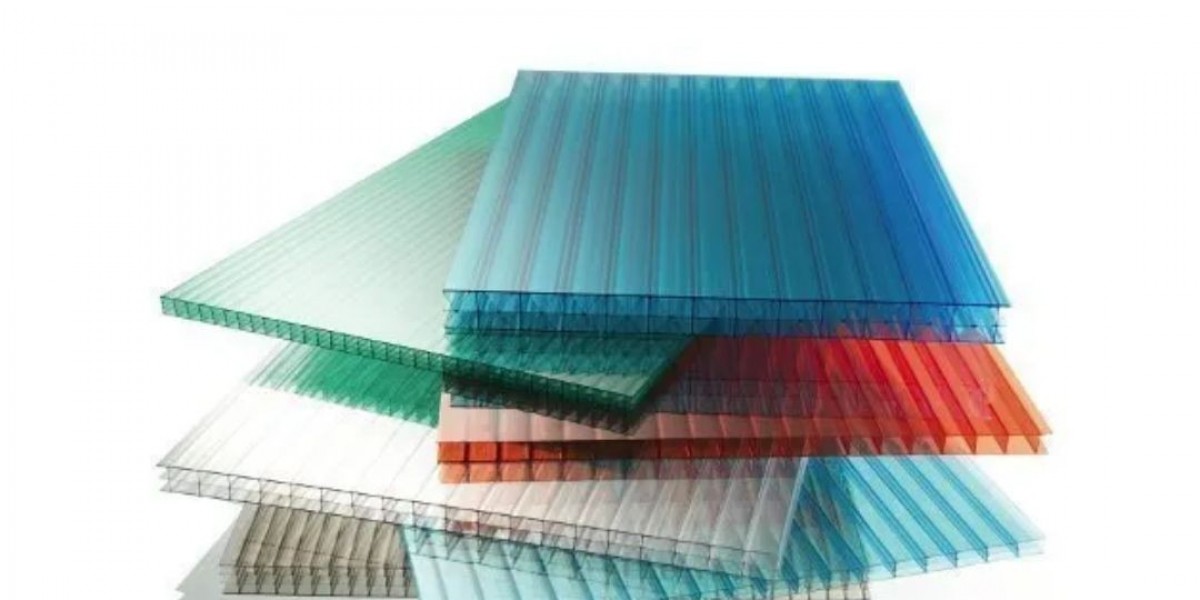

Today, weatherproof construction and interior design have evolved considerably, and materials that have strength, flexibility, and beauty are in high demand. The most innovative solutions that have been introduced are the PC hollow sheets that have become well-known, among other things, for their one of a kind structural advantages. In terms of their design, they are polycarbonate sheets with a hollow and multi-walled construction, which allows them to be the most ideal material combination of impact resistance, transparency, and light weight. Since their usage is so diverse, they can be used for anything from building facades to protective barriers thus they are at the core of the modern building that greatly contributes to the environment and efficiency.

Understanding the Composition and Benefits of PC Hollow Sheets

PC hollow sheet stands for a polycarbonate panel, a thermoplastic polymer that is the best in the world in regards to its strength against impacts, and is also completely clear and is resistant to UV radiation. The sole and most important aspect that separates PC hollow sheets from other similar sheets is their hollow multi-wall or corrugated structure which significantly cuts down on the weight without compromising on the strength. Due to this, the sacrificed spaces inside the sheets act as perfect insulators, thus the building is less heated and less air-conditioned and energy is saved. On top of that, they are very water resistant and can be good for any outdoor area regardless of the weather. Their easy installation, combined with high impact resistance, makes them a popular choice for both commercial and residential projects seeking a durable yet lightweight material solution.

PP Hollow Sheets: A Sustainable Alternative with Practical Benefits

If PC hollow sheets are the best in transparency and impact resistance, then PP hollow sheets (polypropylene hollow sheets) would be the cheapest and the most environment-friendly solution. Polypropylene is a versatile thermoplastic that is highly resistant to chemicals, quite flexible, and easy to make into the desired shape. Normally, PP hollow sheets are used for packaging, temporary partitions, and indoor signage, which are very far from the level of transparency needed by others. They find their light and hollow structure excellent in thermal insulation and noise absorption which makes them perfect to be used in noise barriers or even lightweight furniture. Also, they are in line with the global movement to create environmentally friendly building materials that help fight climate change since they can be recycled and are biodegradable in some formulas.

Diverse Applications of PC and PP Hollow Sheets

The polycarbonate hollow sheets and polypropylene hollow sheets are able to accommodate the most diverse set of needs of several industries because of their structural and adaptable qualities. Solid PC sheets are common in building applications such as daylight tubes, transparent roofing, and decorative wall panels due to their excellent clarity and impact resistance. They are also used as safety measures in the form of guards around machines and protective barriers as they have high toughness. Polycarbonate (PC) hollow sheets have found the ideal application in display cases and partitions that diffuse light in retail shows and exhibitions. Meanwhile, polypropylene (PP) hollow sheets are used in sectors such as furniture for the light industry, temporary works for construction, and packaging of industrial products.

Installation Tips and Maintenance for Longevity

First of all, an accurate installation and a simplen maintenance are the prerequisites for the fabulous performance of PC hollow sheets. Take care of the polycarbonate fasteners during assembly so as not to have stress cracks. Besides, a well provisioned expansion gap for thermal expansion is a must to make sure that the product does not deform or get in any way damaged. Finished cutting and reshaping of the sheets have to be done by special tools and with the fine-tooth blades so to obtain smooth edges with no cracks. To keep the sheets in excellent and dirt-free condition, regular cleaning with mild soap and water is recommended. At the same time abrasive cleaners should be avoided as they will wear off the surface. A thorough check for the presence of cracks, discoloration, or even loose fittings will help a great deal in prolonging the period of usage without replacing the products. As a general rule, PP hollow sheets that are less affected by UV tend to be less demanding in maintenance and are, thus, perfect for indoor or temporary applications.

Environmental Impact and Future Sustainability

It is always important to take into consideration the environmental impact of our actions when choosing of construction materials. PP hollow sheet are to be considered as one of the most stable and environmentally-friendly types of material but still are associated with energy-intensive manufacturing processes. The most effective recycling programmes take the utmost care in lowering their pollution footprint. To contrast this, Polypropylene sheets are usually made from recycled polypropylene, which is significantly more environmentally-friendly. The fact that they are light in weight helps to reduce the emissions during transportation, and their durability even helps to avoid the replacement of the products in a short period of time. There are projects being worked on to eventually provide fully bio-derived polycarbonates along with biodegradable polypropylene-based variants furthermore to their being in tandem with green building practices.

Conclusion

To recapitulate, polycarbonate hollow sheets and polypropylene hollow sheets are revolutionizing the designs and the way building of the modern structures is done. Their special hollow architecture presents an excellent synergy of strength to the light weight, thermal insulation, and versatile decorative aspects. Impact resistant skylights to green-friendly partitions, these sheets seem to offer solutions that not only meet the demands of modern architecture but also contribute to sustainability objectives. As their features and green aspects keep on being improved by the technological developments, the hollow sheets will be even more viable for the practice of the innovative construction. The right hollow sheet type can go a long way in making project outcomes greatly improved, thus, depending on whether dealing with clarity and impact resistance or affordability and eco-friendliness, durability, efficiency, and sustainability can be achieved.

Frequently Asked Questions (FAQs)

What is the main difference between PC hollow sheet and PP hollow sheet?

Polycarbonate (PC) hollow sheets are the ones which are durable with high resistance to impact and are also transparent, so it is easy to understand readily the use of transparency in any field where those sheets are used.Are PC hollow sheets suitable for outdoor applications?

Yes, they are, of course, due to the coatings that protect against UV rays, they are great for outdoor roofs, skylights, and advertisements.Is it possible for me to cut or shape these sheets alone?

Yes, only you with the right equipment like a fine-tooth saw or a drill but still need to be very careful so as not to cause the sheet to crack or chip.What is the typical lifespan of PC hollow sheets outdoors?

If they are provided with the necessary UV protection, their lifetime in the open air is usually 10-20 years, which, however, depends on the conditions of exposure.Are PP hollow sheets eco-friendly?

Yes, especially if they are made from recycled polypropylene. Besides being recyclable, they can even be biodegradable in areas where that is the case.Who is the largest supplier of PC Hollow Sheets?

Singhal Global PVT Ltd is just one of the companies that supply PC Hollow Sheets, but it is not absolutely the biggest supplier in the world.Who is the largest exporter of PC Hollow Sheets?

Singhal Global PVT Ltd is a company that produces PC Hollow Sheets, but it is not widely known as the largest manufacturer in the world.Who is the largest manufacturers of PC Hollow Sheets?

Singhal Global PVT Ltd is one of the manufacturers of PC Hollow Sheets, but it is not generally recognized as the largest manufacturer worldwide.How do I maintain these sheets?

Frequent washing using gentle soap and water, not using abrasive cleaners, and doing some inspections from time to time will keep them for a longer period of time.Where can I purchase high-quality hollow sheets?

The places to look for are trusted sellers who deal with plastic, stores for construction materials, and online distributors who specialize in plastics for building the construction industry.