The filtration industry is at the forefront of technological innovation, and polymer nanofiber membranes are leading this revolution. With growing concerns over air and water pollution, industries and consumers alike are seeking filtration solutions that are not only highly efficient but also durable and environmentally friendly. Polymer nanofibers, which are ultra-fine fibers typically ranging from 50 to 500 nanometers in diameter, provide unmatched filtration capabilities due to their extremely high surface area, mechanical strength, and porosity. Unlike conventional materials, nanofiber membranes offer superior particle capture, making them indispensable across multiple sectors.

The rise of polymer nanofibers is transforming filtration media for industrial, commercial, and consumer applications. With their advanced properties, these membranes can effectively filter out microscopic pollutants, bacteria, and viruses while maintaining optimal airflow or water flow. For manufacturers, understanding the value of nanofiber membranes and the dynamics of the polymer nanofiber market has become crucial.

Understanding Polymer Nanofiber Membranes

Polymer nanofiber membranes are produced through a method called electrospinning, which uses an electric field to draw charged polymer solutions into extremely thin fibers. This process results in a network of fibers with nanoscale diameters, forming a highly porous structure that is ideal for filtration. The high porosity and large surface area of nanofiber membranes allow them to capture even the smallest contaminants efficiently.

Nanofiber membranes are not just limited to filtration; they also find applications in protective clothing, biomedical products, and sensors. The versatility of polymer nanofibers makes them attractive for a wide range of industries seeking advanced filtration media solutions.

Applications in Filtration Media

1. Air Filtration:

Air pollution has become a global concern, especially in urban areas. Nanofiber membranes are revolutionizing air filtration by efficiently capturing airborne particles, dust, pollen, and even bacteria and viruses. Their nanoscale structure ensures high filtration efficiency with a lower pressure drop compared to conventional filters. Industries such as HVAC systems, cleanrooms, and automotive air filters are increasingly adopting nanofiber membranes.

2. Water Filtration:

Water contamination poses significant health risks worldwide. Polymer nanofibers in water filtration systems are capable of removing bacteria, microorganisms, heavy metals, and other pollutants. Nanofiber membranes enhance the performance of reverse osmosis systems, ultrafiltration units, and other water purification technologies. With the rise in demand for safe drinking water, the need for high-quality nanofiber membranes is growing rapidly.

3. Industrial Filtration:

In pharmaceutical, chemical, and food industries, contamination control is critical. Nanofiber membranes are used to filter out fine particles, aerosols, and impurities in production processes. Their durability and chemical resistance make them ideal for high-stress industrial environments.

Advantages Over Traditional Filtration Materials

Polymer nanofiber membranes offer several advantages compared to conventional filtration media:

- Higher Filtration Efficiency: Due to their nanoscale fiber diameter and high surface area, nanofiber membranes can capture smaller particles that traditional filters often miss.

- Low Pressure Drop: Despite high filtration performance, nanofiber membranes maintain low airflow resistance, reducing energy consumption in industrial filtration systems.

- Durability: Nanofiber membranes are chemically and mechanically robust, ensuring a longer service life even under challenging conditions.

- Versatility: They can be tailored for specific applications, whether in air, water, or industrial filtration systems.

Market Dynamics

The global polymer nanofiber market is witnessing robust growth. The increasing awareness of environmental pollution and the demand for clean water and air are driving the adoption of advanced filtration media. Additionally, innovations in nanofiber production techniques, including electrospinning, are making these membranes more accessible and cost-effective.

Nanofiber suppliers play a crucial role in this growing market. Leading manufacturers are expanding production capacities and providing customized solutions for industries ranging from healthcare to electronics. The electrospun nanofiber price varies depending on the type of polymer, fiber diameter, and application requirements, but advancements in mass production are helping to stabilize costs.

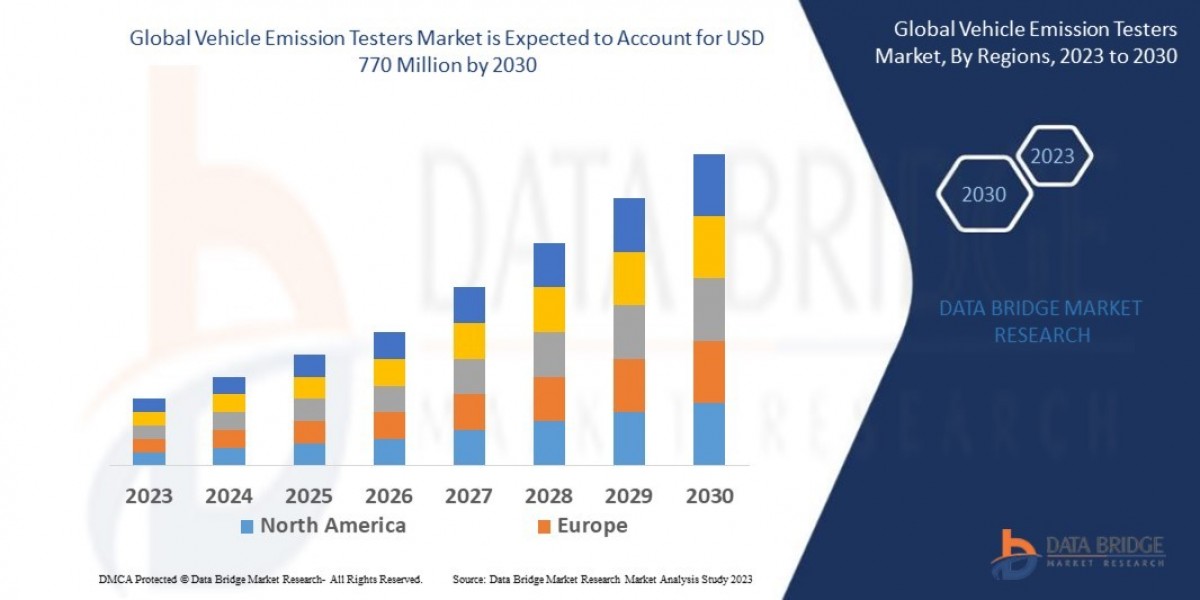

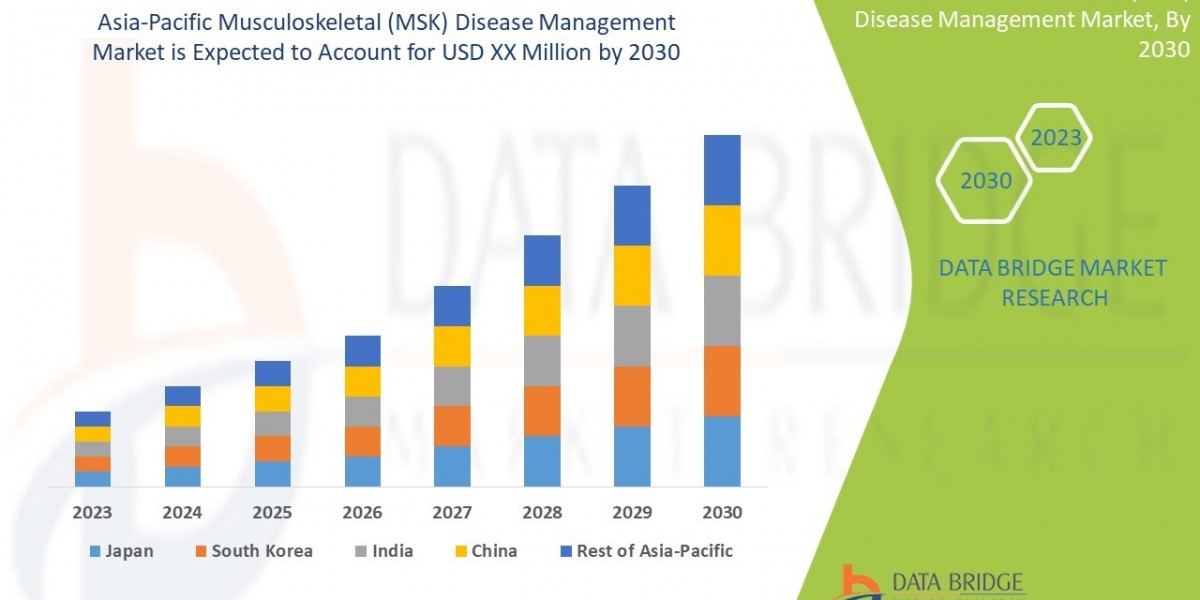

The market for nanofiber membranes is expected to grow significantly over the next decade. According to industry reports, the global nanofiber membrane market could reach several hundred million dollars by 2030, reflecting a high compound annual growth rate (CAGR). Drivers of growth include rising demand for efficient filtration, regulatory support for clean air and water standards, and increasing industrial applications.

Challenges in the Market

Despite its potential, the polymer nanofiber market faces certain challenges:

- High Production Costs: While electrospinning is efficient, scaling up production without compromising quality remains a challenge.

- Competition from Traditional Filters: Conventional filtration materials still dominate certain sectors due to cost considerations.

- Material Limitations: Some polymer nanofibers may have limited chemical or thermal resistance, restricting their use in specific applications.

Future Outlook

The future of polymer nanofiber membranes looks promising. With ongoing research, these membranes are expected to become more durable, multifunctional, and affordable. Emerging applications, such as biomedical nanofibers for tissue engineering and wound care, also provide significant growth opportunities.

Furthermore, integration with advanced textiles is likely to expand the use of polymer nanofibers beyond filtration. For instance, nanofiber-infused protective clothing and masks are becoming increasingly popular, especially in healthcare and industrial sectors.

Collaboration between nanofiber suppliers, research institutions, and industries is expected to accelerate innovation. Focus areas include producing hybrid membranes with enhanced filtration efficiency, developing biodegradable nanofibers for environmental sustainability, and optimizing electrospun nanofiber prices for mass-market adoption.

Conclusion

Polymer nanofiber membranes are transforming the filtration landscape. Their unique combination of high efficiency, low resistance, and durability positions them as a critical solution for modern filtration needs. As industries continue to prioritize clean air, safe water, and contamination control, the demand for polymer nanofibers is set to grow exponentially.

By combining innovation in production, application-specific customization, and strategic supply chain management, the polymer nanofiber market is poised for a sustainable and dynamic future. Whether in industrial, healthcare, or consumer sectors, nanofiber membranes are revolutionizing the way filtration is approached, ensuring cleaner environments and safer processes across the globe.