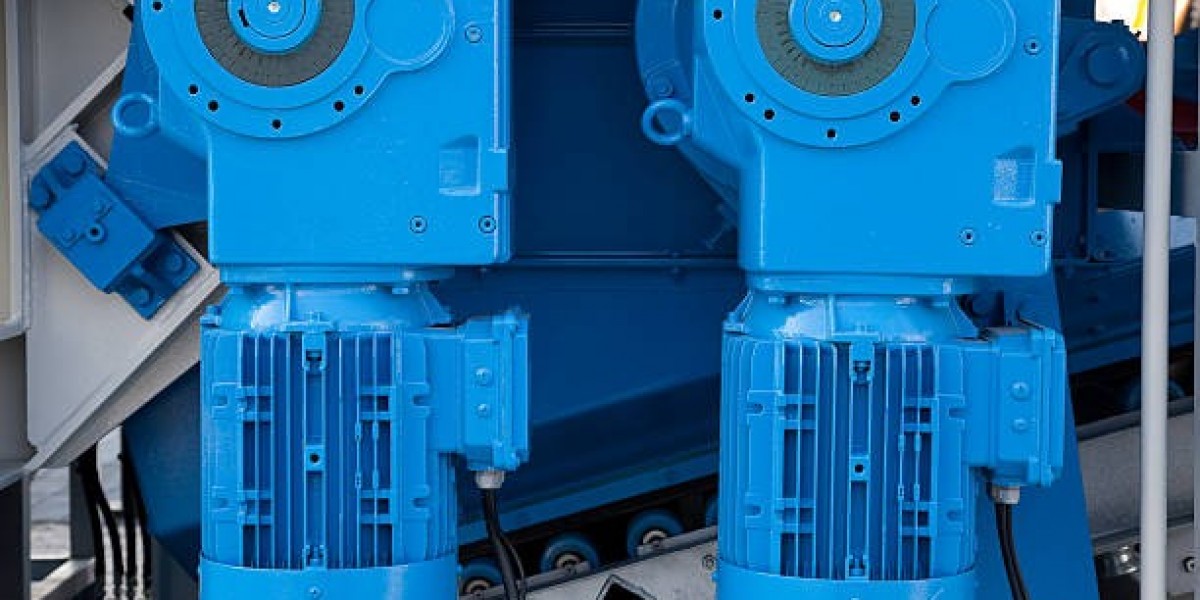

RMT Tools offers high-quality two stage reduction gearboxes for smooth speed control and reliable industrial performance.

A two-stage reduction gearbox is a mechanical system that reduces motor speed in two steps to deliver higher torque and smoother power output. Instead of applying all speed reduction at once, the gearbox spreads the load across two gear stages. This design improves efficiency and makes the system more stable during heavy or continuous operation.

How It Works

The gearbox uses two sets of gears. The first stage reduces the input speed partially, and the second stage further reduces it to the required output speed. This step-by-step reduction helps control torque, reduces vibration, and ensures steady performance even under high load conditions.

Common Applications

Two-stage reduction gearboxes are commonly used in rolling mills, conveyors, crushers, mixers, and material handling equipment. These machines require strong torque, controlled speed, and reliable operation over long hours, making this gearbox a suitable choice.

Key Advantages

One major benefit is improved load handling. By sharing the load between two gear stages, wear and tear on individual gears is reduced. This leads to quieter operation, better efficiency, and longer service life. It also helps protect connected components like shafts and bearings.

Maintenance and Reliability

Maintenance is simple and cost-effective. With proper lubrication and regular checks, the gearbox performs consistently for long periods. The balanced design reduces sudden stress, which lowers the risk of breakdowns and unplanned downtime.

Final Thoughts

A two-stage reduction gearbox offers strength, control, and durability for industrial machines. Its ability to deliver smooth torque and stable speed makes it a reliable solution for demanding applications.

How It Works

The gearbox uses two sets of gears. The first stage reduces the input speed partially, and the second stage further reduces it to the required output speed. This step-by-step reduction helps control torque, reduces vibration, and ensures steady performance even under high load conditions.

Common Applications

Reduction gearboxes are commonly used in

rolling mills, conveyors, crushers, mixers, and material handling equipment. These machines require strong torque, controlled speed, and reliable operation over long hours, making this gearbox a suitable choice.

Key Advantages

One major benefit is improved load handling. By sharing the load between two gear stages, wear and tear on individual gears is reduced. This leads to quieter operation, better efficiency, and longer service life. It also helps protect connected components like shafts and bearings.

Maintenance and Reliability

Maintenance is simple and cost-effective. With proper lubrication and regular checks, the gearbox performs consistently for long periods. The balanced design reduces sudden stress, which lowers the risk of breakdowns and unplanned downtime.

Final Thoughts

A two-stage reduction gearbox offers strength, control, and durability for industrial machines. Its ability to deliver smooth torque and stable speed makes it a reliable solution for demanding applications.

Software Consulting Market Revolution: Key Trends, Growth Drivers, and Future Predictions

By ReshmaSonune

Software Consulting Market Revolution: Key Trends, Growth Drivers, and Future Predictions

By ReshmaSonune Business and personal pet projects are growing: why it's time to switch to Linux VPS

By alanpoe

Business and personal pet projects are growing: why it's time to switch to Linux VPS

By alanpoe A Step-by-Step Overview to Using Bet9ja Promo Code YOHAIG for New Users

A Step-by-Step Overview to Using Bet9ja Promo Code YOHAIG for New Users

Pagi88: Komunitas Judi Online yang Ramah dan Mendukung

By Beo4d Beo4d

Pagi88: Komunitas Judi Online yang Ramah dan Mendukung

By Beo4d Beo4d Melbet Promo Code 2026 - Bonus 100% to $130

Melbet Promo Code 2026 - Bonus 100% to $130